TM 5-2420-230-24-2

B3.9 and B5.9 Series Engines

Fuel Drain Line Restriction (006-012)

Section 6 - Injectors and Fuel Lines - Group 06

Page 6-5

Test (006-003-012)

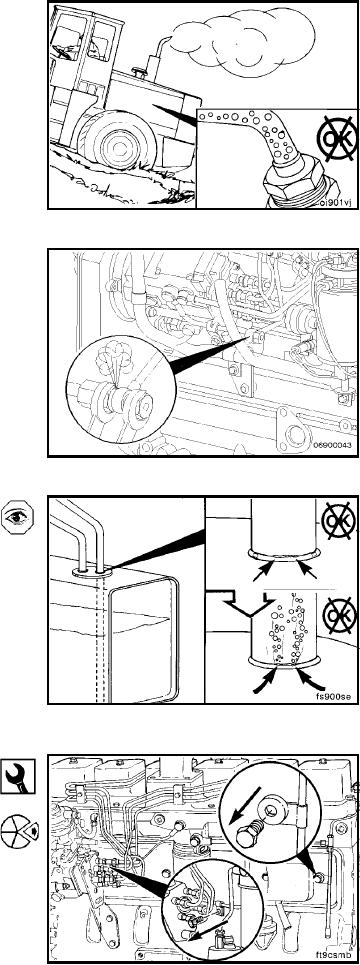

A replacement of fuel supply lines, fuel filters, fuel injection

pump, high-pressure fuel lines, and injectors will let air

enter the fuel system. Air in the system will make the engine

hard to start, run rough, misfire, produce low power, and

can cause excessive smoke and a fuel knock.

NOTE: If an excessive amount of air has entered into the

system, the system will need to be bled.

Loosen the return banjo fitting on the fuel lift pump. Run the

fuel lift pump until all the air has been bled. When all the

air has been bled, retighten the fitting.

NOTE: To run the fuel pump for 25 seconds, crank the

engine for a split second, and leave the key in the ON

position.

If air continues to bubble out of the system for several

minutes, then an air leak is present.

An often overlooked source from which air can enter the

fuel system is between the inlet of the fuel transfer pump

and the suction tube in the tank. Fuel tanks that have the

outlet fitting at the top will have a suction tube that extends

to the bottom of the tank. Cracks or pin holes in the weld

that join the tube to the fitting can let air enter the fuel

system.

Also, check to make sure all the fittings from the fuel supply

line on the tank to the inlet of the fuel transfer pump are

tight.

Use a sight glass at the fuel lift pump inlet to check for air

in the fuel supply lines.

Fuel Drain Line Restriction (006-012)

Measure (006-012-010)

10 mm

Remove the capscrews from the hold-down clamps, and

complete the following steps:

L-975