TM 5-3805-280-24-1

Operational Checkout Procedure

SPROCKET WEAR

Inspect drive sprocket.

YES: Replace sprocket.

CHECK

Go to Group 0130.

Is tooth wear excessive?

NO: Go to next check.

NOTE: Do not evaluate sprocket by condition of tooth

tip. Tooth tip wear does not affect sprocket operation if it

9005

does not extend into the bushing contact area.

10

20

NOTE: Reverse drive side wear is generally more than

T6981AC

UN13MAR89

forward drive side wear.

1/1

GROUSER WEAR, BENT

Inspect for worn grousers, bent track shoes, and loose

YES: If shoe hardware is

TRACK SHOE, AND

shoe hardware.

loose, remove shoe and

LOOSE HARDWARE

clean joint before

CHECKS

tightening. Go to Remove

Are grouser bars worn excessively?

and Install Track Shoe in

Group 0130.

Are track shoes bent?

NO: Go to next check.

Is track shoe width appropriate for ground condition?

T7322AF

UN21JUN90

Is track shoe hardware tight?

NOTE: Excessive grouser wear weakens track shoes

and may result in track shoes bending.

1/1

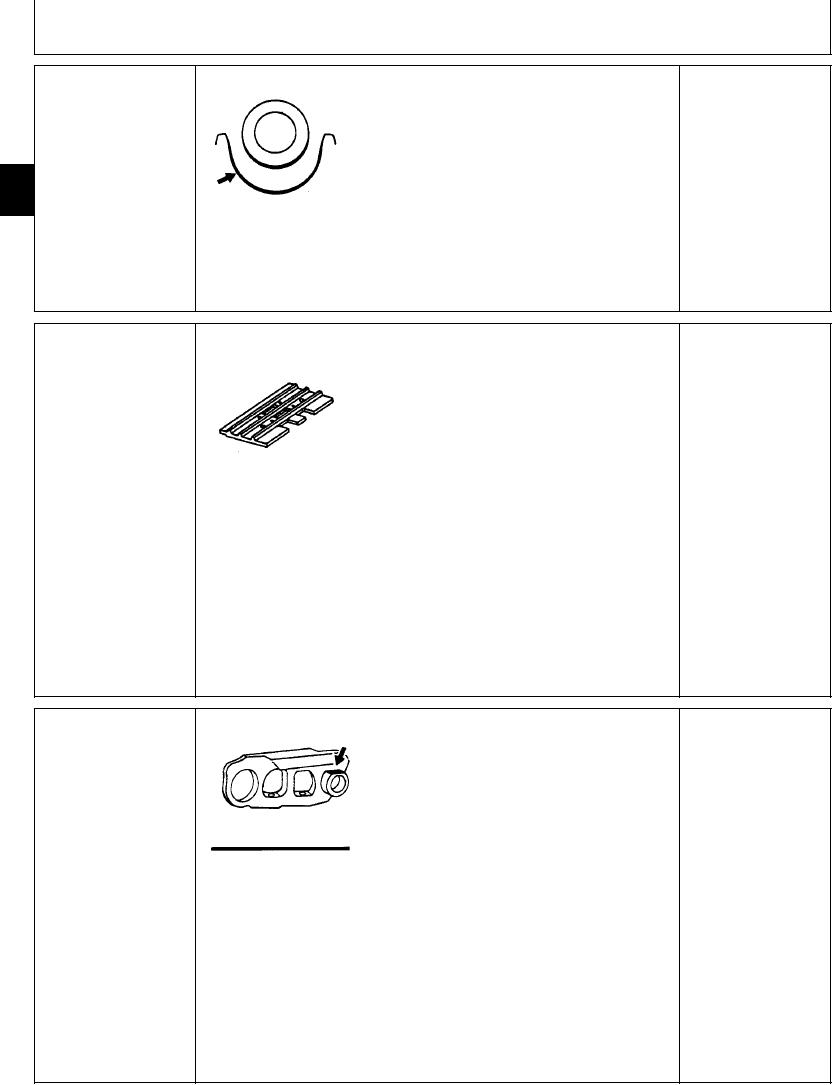

TRACK LINK ROLLER

Inspect track links for pin boss wear.

YES: Go to

AND FRONT IDLER

Undercarriage Appraisal

WEAR CHECKS

Manual SP326 for more

Do link pin boss areas indicate contact with roller flanges

information and

or track guides?

specifications.

NOTE: Some contact or wear is normal. Excessive

contact or wear indicates excessive rail wear.

NO: Go to next check.

Inspect front idler flanges.

T6484AZ

UN19OCT88

Do idler flanges contact bushings?

NOTE: Idler contact with bushings indicates excessive

chain rail wear and idler tread surface wear.

1/1

2-20