TM 5-3805-280-24-1

Theory of Operation

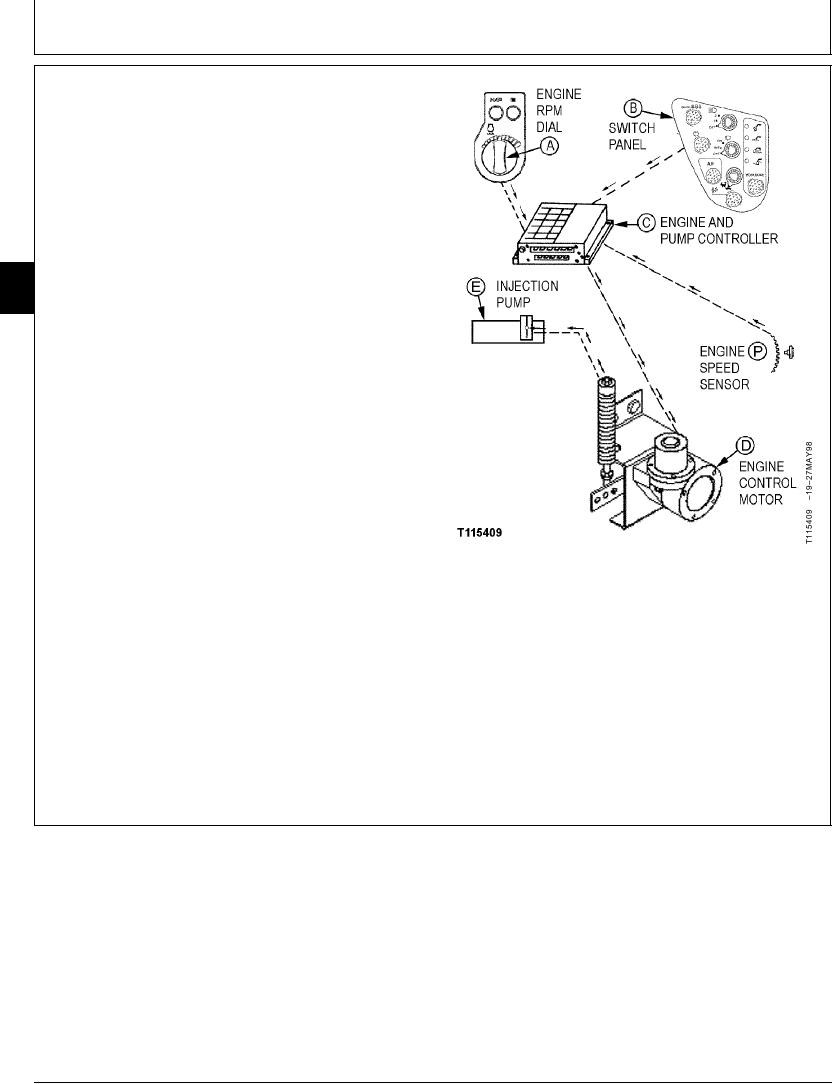

The engine speed control components allows the operator

to choose engine speeds to match operating conditions

and to operate the engine as efficiently as possible.

Engine speeds from slow idle to fast idle in standard

mode are selected by the engine rpm dial (A) located in

the right console panel in cab. The E (economy) mode

and HP (high power) mode are selected by switches

located in the right console panel just above the engine

rpm dial. The auto idle mode is selected by a switch

located in the switch panel (B). Indicators in the monitor

9010

05

panel are lit to indicate when the E mode, HP mode, and

4

auto-idle mode switches are pushed to activate the

function.

AI=Auto Idle Mode Switch

E=Economy Mode Switch

HP=High Power Mode Switch

Turning the engine rpm dial or pushing the AI, E, or HP

mode switches sends an electrical signal to the engine

and pump controller (C). The controller senses the

electrical signal and then from the stored data sends an

electrical signal to the engine control motor (D). The

engine control motor regulates engine speed by a

push-pull cable attached to the fuel injection pump lever

located in the pump drive housing.

The engine speed sensor (P) (located in the pump drive

housing) counts the pump drive gear teeth as the gears

rotate. This senses actual engine speed. The sensing

signal is sent to the engine and pump controller (C) which

calculates engine speed.

CED,OUOE035,146

1911AUG982/2

3-4