TM 5-3805-280-24-1

Tests

2. Check radial runout by positioning a dial indicator so

probe contacts dampener OD.

3. With engine at operating temperature, rotate crankshaft

using flywheel turning tool.

4. Note dial indicator reading. If radial runout exceeds

specification, replace torsional dampener.

Torsional Dampener--Specification

9010

Radial Runout............................................. 1.50 mm (0.060 in.) maximum

25

12

CED,OUOE003,1059

1912AUG982/3

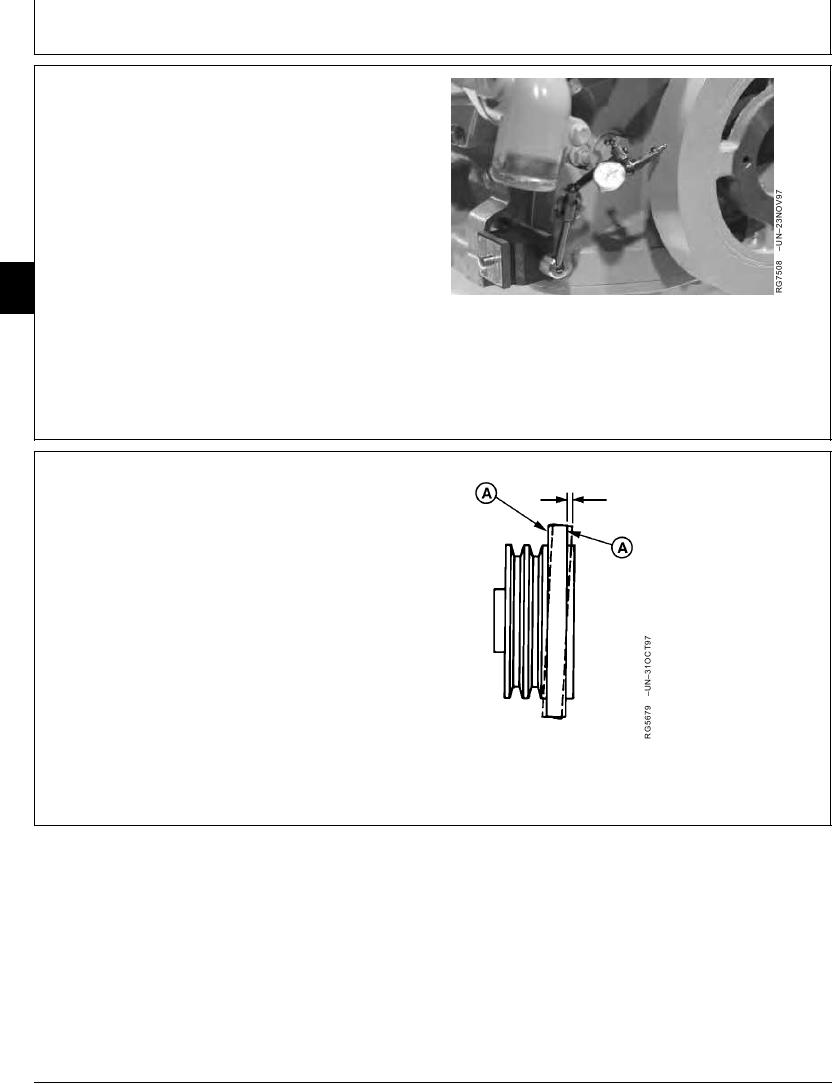

5. Check axial runout (wobble) using a dial indicator.

Measure axial runout at the outer edge of dampener

face (A).

6. Rotate crankshaft one complete revolution using

flywheel turning tool. Note total dial indicator reading. If

axial runout exceeds specification, replace torsional

dampener.

Torsional Dampener--Specification

Axial Runout (Wobble) ............................... 1.50 mm (0.060 in.) maximum

A--Torsional Dampener Face

CED,OUOE003,1059

1912AUG983/3

3-63