TM 5-3805-280-24-1

Theory of Operation

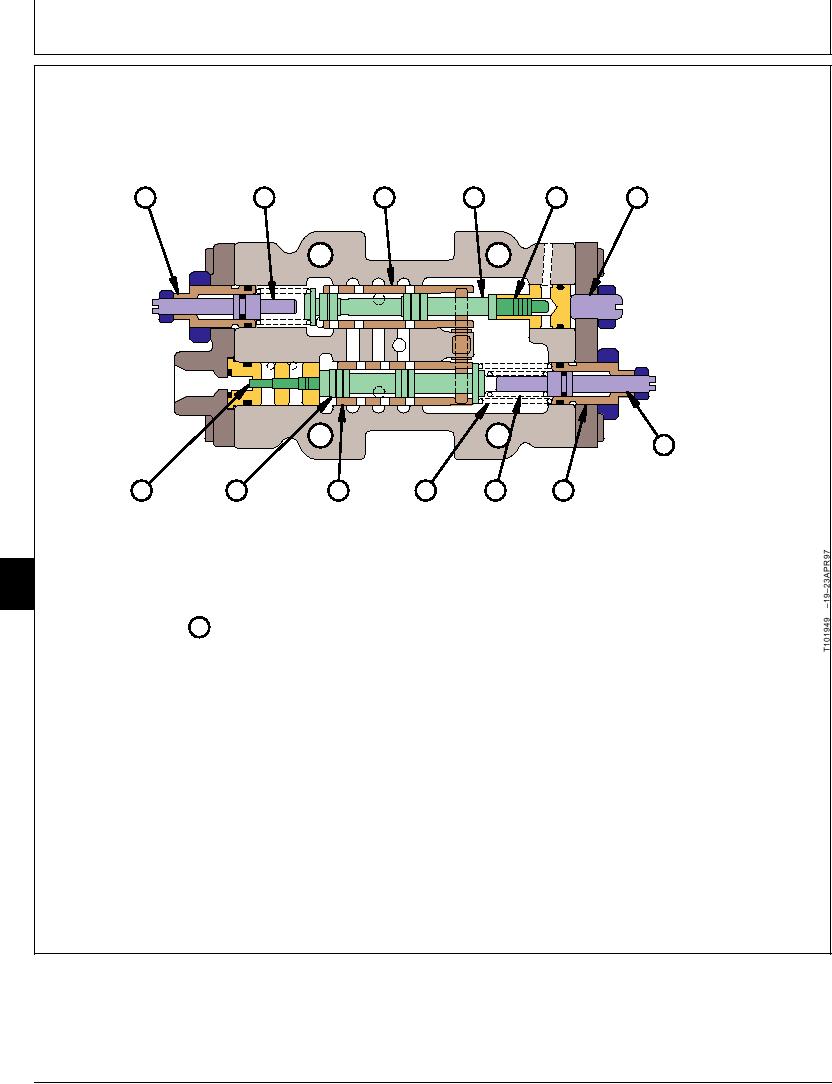

HYDRAULIC PUMP REGULATOR COMPONENT OPERATION

FLOW ADJUSTING

REMOTE

MAXIMUM FLOW REMOTE

CARTRIDGE

MINIMUM FLOW

CONTROL

CONTROL

(TRACK CYCLE

ADJUSTING

ADJUSTING

PISTON

SPOOL

SLEEVE

TIME)

SCREW

SCREW

A

B

C

D

E

F

G LOAD

ADJUSTING

SCREW

(INNER SPRING)

M

L

K

J

I

H

(ENGINE

OUTER INNER LOAD

LOAD

LOAD

LOAD

PULLDOWN AT

SPRING SPRING ADJUSTING

SLEEVE

PISTON

SPOOL

HIGH PRESSURE)

CARTRIDGE

(OUTER SPRING)

9025

(ENGINE

05

PULLDOWN AT

18

MEDIUM PRESSURE)

N PUMP REGULATOR COMPONENTS

T101949

sleeve (K), load spool (L), and load piston (M). Each

The pump regulators are mounted on the top of the

regulator controls the flow of pilot oil to the large end

hydraulic pump housing. The major pump regulator

of its servo piston using the spools and sleeves.

components (N) are the flow adjusting cartridge (A),

maximum flow (displacement) adjusting screw (B),

The remote control spool (D) is moved by a reduced

remote control sleeve (C), remote control spool (D),

pilot oil control signal from front and rear pump control

piston (E), minimum flow (displacement) adjusting

valve. There is a pump control valve located in the left

screw (F), load adjusting screw (inner spring) (engine

and right control valves. The control signal acts on the

pull down at high pressure) (G), load adjusting

end of the piston (E) to control the position of remote

cartridge (outer spring) (engine pull down at medium

control spool against the spring.

pressure) (H), inner spring (I), outer spring (J), load

Continued on next page

TX,05,GG2148 1919MAY981/2

6-17