TM 5-3805-280-24-1

Theory of Operation

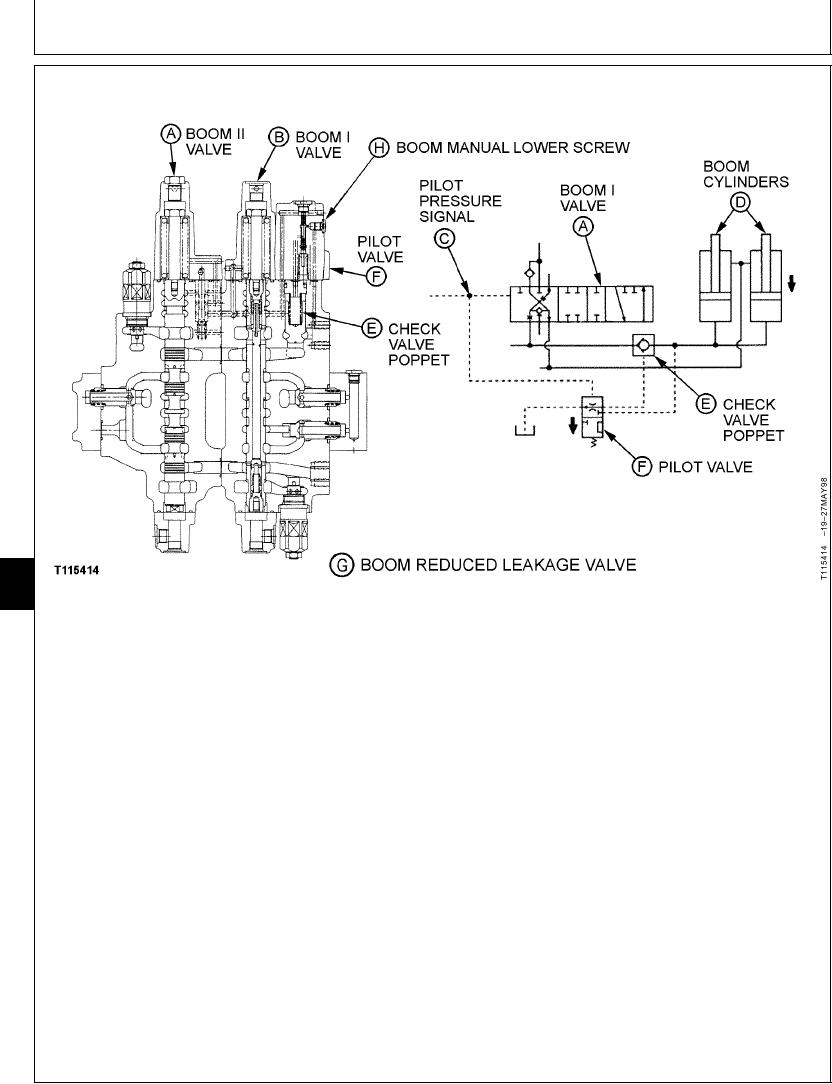

BOOM AND ARM REDUCED LEAKAGE VALVES OPERATION

9025

05

52

shifts the pilot valve (F). The oil pressure from the

Reduced leakage valves (G) are used in the boom

cylinder is blocked by the pilot valve. The oil pressure

head end circuit and arm rod end circuit. The function

at the top (spring end) of check valve poppet can now

of a reduced leakage valve is to reduce cylinder drift

flow through the pilot valve to the warm-up passage in

by stopping leakage from the cylinder back through the

the pilot caps and then to the hydraulic oil tank. The oil

control valve.

pressure from the cylinder pushes the poppet off its

seat opening the passage for oil to flow into the control

When the control valve is in neutral, the oil pressure

valve return passage. The poppet is pushed off its seat

generated in the boom cylinder head end or arm

because the OD of upper land at the head end of

cylinder rod end by the load on the cylinders is applied

poppet is slightly larger than the lower land.

to the top (spring end) of check valve poppet (E)

through the pilot valve (F). The poppet is held closed

The boom manual lower screw (H) is used to lower the

against the seat in housing trapping the oil from the

boom if the engine should stop with the boom in the

cylinder at the work port.

raised position. (See Lower Boom With Engine

Stopped in Group 9025-25.)

When boom down or arm in function is actuated, the

pilot pressure signal (C) from the pilot controller also

TX,05,GG2186 1920MAY981/1

6-49