TM 5-3805-280-24-1

Troubleshooting procedure for rod changer

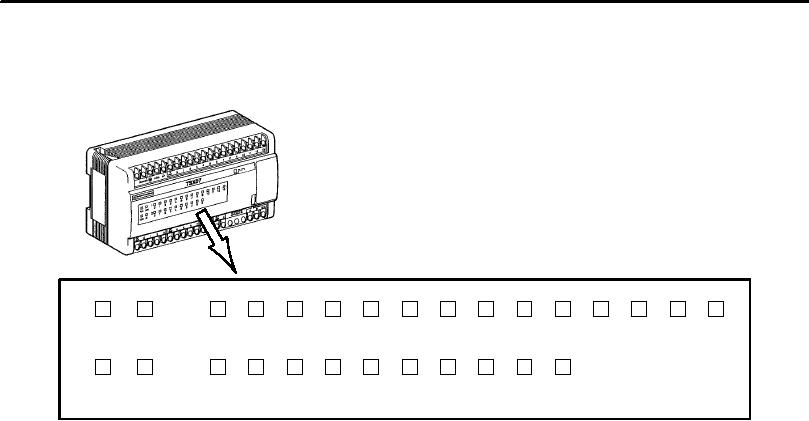

CHECKING OF PLC

The result of PLC autotest and the state of each input / output can be visualized on the front panel of the PLC.

I

RUN ERR

0

1

2

3

4

5

6

7

8

9

10

11

12

13

O

COM I / O

0

1

2

3

4

5

6

7

8

9

Autotest

The "RUN" indicator must be alight when the CPA is under tension.

"ERR", "COM" and "I / O" indicators must be off.

If not, the PLC is faulty and must be replaced (be sure all fuses are OK).

Inputs / outputs

Input indicators (I 0 to I 13) or output indicators (O0 to O9) are alight when the corresponding input / output is active.

CHECK LIST

Follow the check list to determine if all input and output information are entering and leaving the PLC properly.

State (alight or off) of the indicators must be conform to the list. If not, check the input / output wiring and

components (refer to electric diagrams 94707 and / or 94831).

Note : some other indicators should be alight or off at the same time, only consider the state of the listed one.

Prior proceeding the following tests, remove the starter rod from the guide and make sure

the drifter is pulled back.

Note: If the carousel rotation is working in manual mode but not in automatic mode (rod adding or rod removing) ,

check the output indicators O0 or O1 are alight (depending of the carousel direction of rotation).

10-28