TM 5-3805-280-24-1

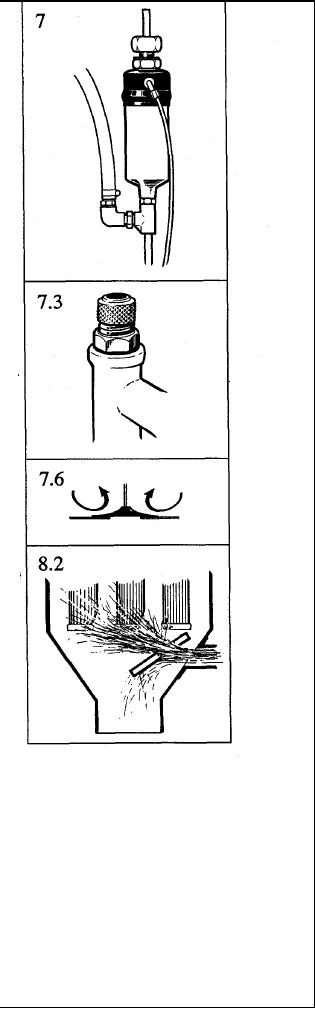

7.AIR CYLINDER

7.1If air cylinder puts the fan closer plate in

closed position during drilling, the dust

collector does not work.

Check diaphragm C) in the 1/2" solenoid

valve that controls air cylinder movements.

If diaphragm is broken, change to a new one.

If hole is clogged, blow clean.

7.2

Check solenoid by simulating a cleaning

cycle as described in 5.2 above.

7.3

Check and clean the adjustable relief valves.

NOTE! After refitting adjustable relief valves you

must adjust them to achieve correct movements of

air cylinder.

How to adjust

Open relief valve by turning 2.5 turns from closed.

7.4

Check and clean the bleed filter.

7.5

If air cylinder still is not working, change to a

new one.

7.6

Check fan closer plate. Ensure that ass'y is

secure and sealed against bottom plate. This

is very important for perfect filter cleaning and full

suction capacity.

8.

If dust escapes through fan top, one or more

filters arc broken. STOP DRILLING

IMMEDIATELY and check which filters are

broken. Exchange broken filters for new

ones.

IMPORTANT! When opening filter housing from

bottom section, follow instructions given below.

Also check the clean air chamber and clean away

any dust which otherwise can fall down inside the

clean filters. If necessary, clean filter housing and

bottom section.

8.1Check if filters- are clogged. If impossible to

clean, change to new filters.

8.2Check wear plate inside dust collector inlet.

If plate is worn out, high-speed dust will blow directly

into the filters and destroy them in a very short time.

10-34