TM 5-3805-281-10

OPERATOR PREVENTIVE MAINTENANCE CHECKS AND SERVICES

FOR HYDRAULIC EXCAVATOR 330LCR

ITEM

INTERVAL

ITEM TO BE INSPECTED

EQUIPMENT IS NOT

NO.

PROCEDURE: DO THE PMCS AND HAVE ITEM

READY/AVAILABLE

REPAIRED, FILLED, OR ADJUSTED AS NEEDED

IF:

1

Before

Check Fuel Tank (Fill at End of Day)

2

Before

Inspect Boom, Bucket, Arm, Cylinders, and Hoses for Bent,

Any damage that will

After

Broken, Loose, Leaking, or Missing Parts

prevent operation

3

Before

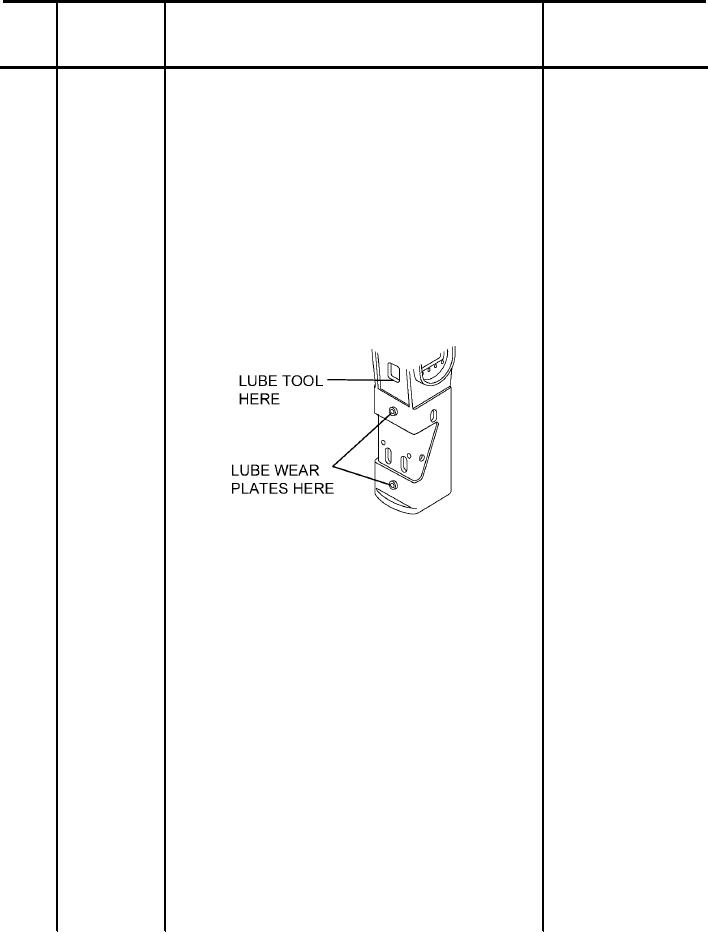

Lubricate Breaker and Wear Plates

During

NOTE: Lubricate the tool every 2 hours. If

working in dusty conditions, lubricate tool

more frequently (every hour). Tool must

always have grease on the hammer contact

area as required.

(1) Lubricate tool with approximately 60 pumps of

INDECO Supreme 1000 grease (or other HD

Moly Grease containing 3 to 5 percent

Molybdenum Disulfide) as shown.

(2) Lubricate wear plates with approximately 2--3

pumps of INDECO Supreme 1000 grease (or

other HD Moly Grease containing 3 to 5

percent Molybdenum Disulfide) for each plate.

4

Before

Inspect Breaker Cradle and Side Shocks for Loose or

Bolts are loose or

Missing Bolts, Cracked Bolts, or Cracks in Cradle

missing; cradle or side

shocks damaged

5

Before

Check Breaker Tool Retainers, Locking Bolts, and Plug

(1) Check tightness of tool retainers in the carrier.

(2) Check tightness of locking bolts.

Locking bolts are not tight

(3) Make sure that the under water plug is in place.

Under water plug is not in place

6

Before

Inspect Breaker Hydraulic Hoses for Leaks or

Hoses are cracked or

Chaffing

leaking

A-4