TM 5-3805-281-10

OPERATOR PREVENTIVE MAINTENANCE CHECKS AND SERVICES

FOR HYDRAULIC EXCAVATOR 330LCR

ITEM

INTERVAL

ITEM TO BE INSPECTED

EQUIPMENT IS NOT

NO.

PROCEDURE: DO THE PMCS AND HAVE ITEM

READY/AVAILABLE

REPAIRED, FILLED, OR ADJUSTED AS NEEDED

IF:

(1) Inspect oil cooling lines and hoses for cracks.

(2) Look for evidence of leakage.

Any Class III leak evident

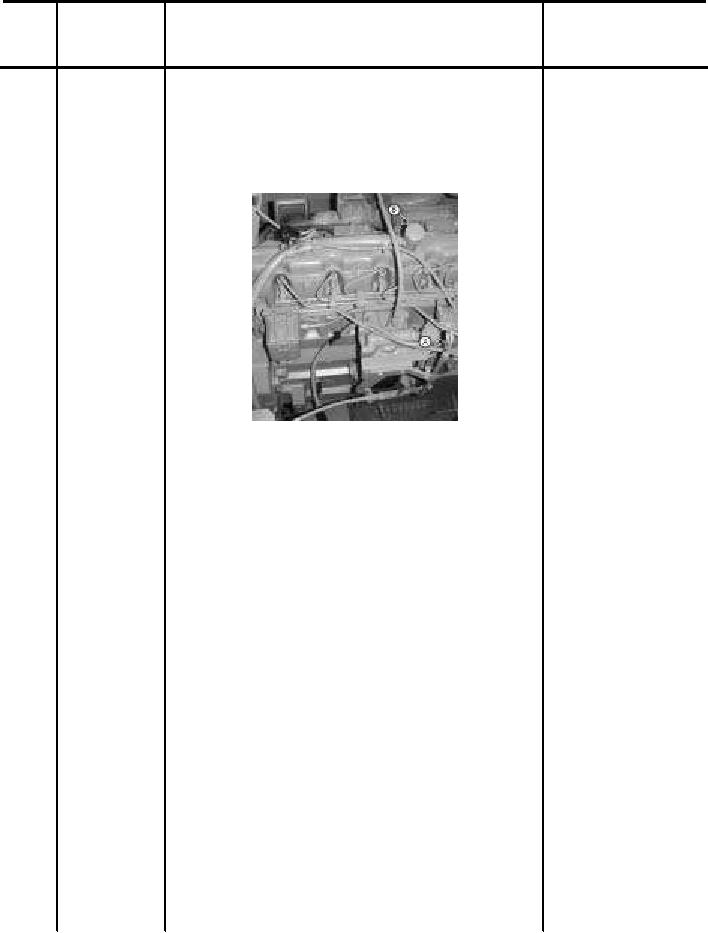

(3) Make sure dipstick (A) is fully seated.

(4) Remove dipstick and check oil level.

(5) Add oil (filler cap [B]) if level is below the

Oil level is below the ADD

ADD or cross-hatched area mark on the

mark on the dipstick

dipstick (see Fuels and Lubricants, Chapter 9).

NOTE: BEFORE THE ENGINE IS

STARTED: The engine is full when oil level is

in the cross-hatched area.

AFTER THE ENGINE HAS BEEN RUN:

Allow the oil to drain into the oil pan for 10

minutes after engine stops before checking the oil

level. The oil level must be above the ADD mark.

If necessary, remove oil filler cap (B) and add oil.

(6) Inspect engine compartment for loose or

Any damage that would

damaged components.

prevent operation

NOTE: Ensure that engine access door is

closed securely after inspection is complete.

A-11