TM 5-3805-281-24-2

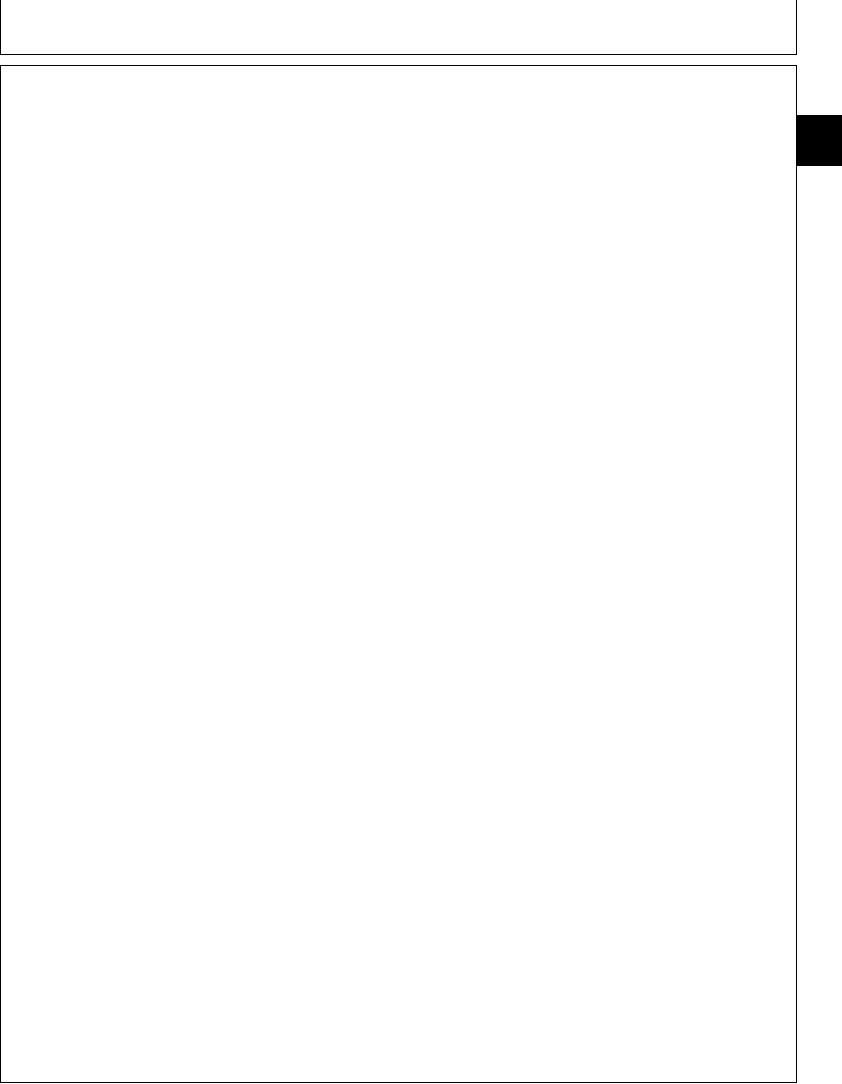

Buckets

1--Quick-Latch Frame

7--Spring Mounting

12--Lock Washer (2 used)

19--Handle Assembly

Assembly

Bracket

13--Nut (2 used)

20--Roll Pin

2--Grease Fitting

8--Cylinder Mounting

14--Hose Clamp

21--Decal

33

3--Wedge

Bracket

15--Cover Plate

22--Cover

3302

4--Spring

9--Elbow

16--Cap Screw

23--Cap Screw (4 used)

17

5--Hydraulic Cylinder

10--Pin Assembly

17--Spring

24--Lock Washer (4 used)

6--Cap Screw (2 used)

11--Cap Screw (2 used)

18--Pin

25--Cap Screw (2 used)

11. Route the two hydraulic lines through the holes in

1. Slide spring (17) over pin (18) and push them up

the latch frame cross member. Connect the lines

through the hole in the rear of the latch frame.

to the elbows (9).

2. Block in the pin with a shim using the slot in the

12. Assemble hydraulic cylinder base side pin (10)

back plate of the frame.

and rod side pin (10) with mounting hardware (11)

and (12). Torque cap screws to 45 lb-ft. Tighten

3. Slide handle assembly onto the pin and align the

nuts (13).

pin bores.

Side Pin Cap Screw--Specification

4. Insert roll pin (20) through pin bore and remove the

shim.

Torque....................................................................................... 45 lb-ft

5. Rotate wedge bar (3) 90 degrees and slide it into

13. Slide the two cap screws (6) through the wedge

the latch frame (1). The wedge taper should be on

bar (3) and rod eye mounting bracket (8). Install

the top and angled down towards the link pin when

the two nuts (13) and tighten to 200 lb-ft. This will

the wedge bar is routed back to it's upright position.

draw the cylinder rod eye mounting bracket,

wedge bar, and spring mounting bracket together.

6. Tilt the top of wedge bar back about 30 degrees.

This will also apply a spring pre-load to the wedge

Slide the two compression springs (4) into the holes

bar.

in the wedge bar.

Wedge Bar Nuts--Specification

7. While the wedge bar is still tilted up, slide the

hydraulic cylinder (5) into the center hole of the

Torque..................................................................................... 200 lb-ft

wedge bar. Slide the cylinder inward eye first and

with the rod port on the right hand side.

14. Route the hydraulic lines so they clear the arm

link. Anchor the lines with hose clamps (14) and

8. Install the two cap screws (6) into the spring

mounting hardware (15) and (16).

mounting bracket (7) and place the bracket on the

end of the two compression springs (4). Rotate the

15. Install cover (22) to the quick-disconnect hitch with

all the parts downward into the latch frame (1).

cap screws (23) and lock washers (24). Torque

the cap screws (24) to 80 lb-ft.

9. Install the two 45 degree elbows (9) with the ends

oriented downwards.

10. Install the cylinder rod eye mounting bracket (8) in

the frame on the rearward side of the wedge.

Continued on next page

CED,OUOE042,5071 1916APR992/3

19-17