TM 5-3805-281-24-2

UNIT PREVENTIVE MAINTENANCE CHECKS AND SERVICES

FOR HYDRAULIC EXCAVATOR 330LCR

ITEM

INTERVAL

ITEM TO BE INSPECTED

EQUIPMENT IS NOT

NO.

PROCEDURE: DO THE PMCS AND HAVE ITEM

READY/AVAILABLE

REPAIRED, FILLED, OR ADJUSTED AS NEEDED

IF:

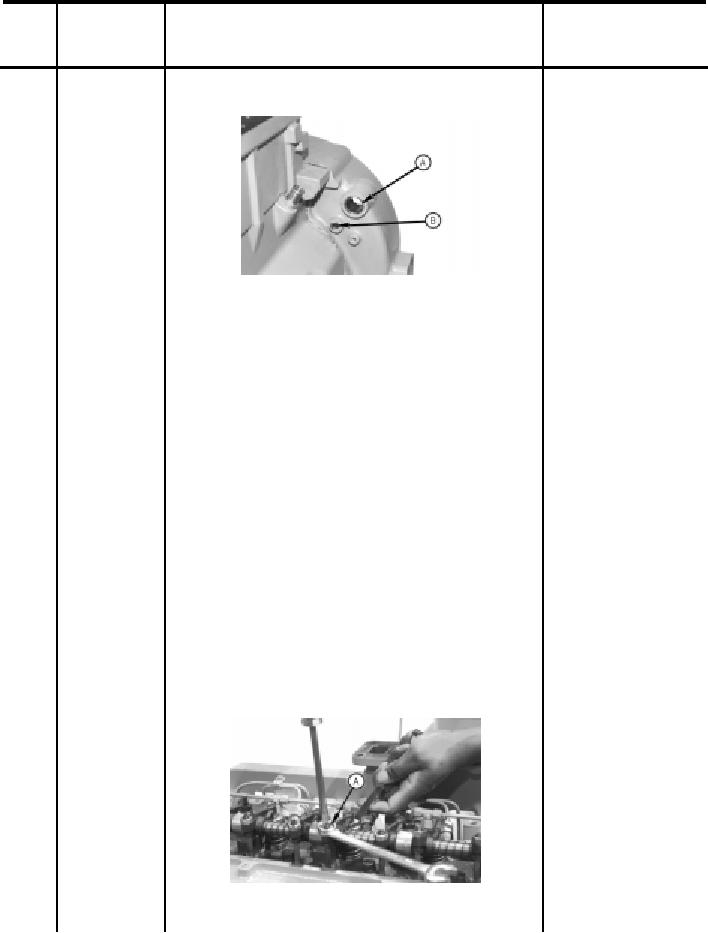

(2) Remove plug (A). Install JDG 820 Flywheel

Turning Tool. Remove cap screw (B). Install

JDE-81-4 Timing Pin.

(3) Turn flywheel until timing pin goes into

flywheel.

(4) Using engine rotation tool, rotate engine

flywheel in running direction (clockwise

viewed from front) until No. 1 cylinder is at

"TDC" Compression stroke.

If No. 1 cylinder rocker arms are loose, the engine

is at No. 1 "TDC" Compression. If No. 1 cylinder

rocker arms are not loose, rotate engine one full

revolution (360) to No. 1 "TDC" Compression.

To change piston position, remove timing pin and

rotate flywheel.

(5) Check and adjust valve clearance to

specifications as directed in following

procedures.

(6) Loosen jam nut (A) and adjust clearance with a

screwdriver, as shown.

A-30