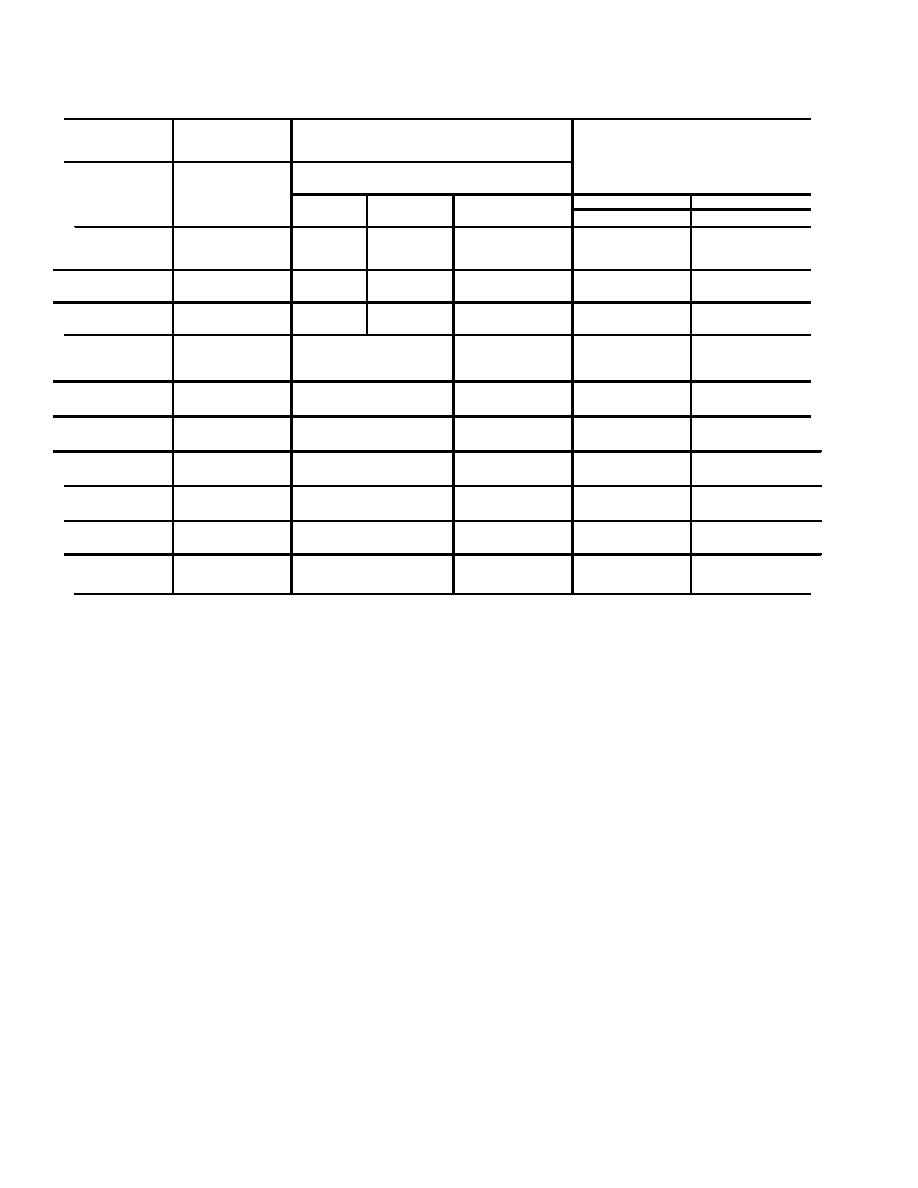

*SB 740-97-38

Master Sampling Table

Lot

Size

Sampling Plan

Acceptance-

Sample Size

Rejection No.

No.

Sample

Cumulative

Major-A

Major-B

Items

No.

Major-A

Major-B

Sample Size

AC

RE

AC

RE

2-8

3

2

0

1

0

1

9-15

3

2

0

1

0

1

16-25

3

3

0

1

0

1

FIRST

8

8

0

2

0

3

26-90

SECOND

8

16

1

2

3

4

FIRST

13

13

0

3

1

4

91-150

SECOND

13

26

3

4

4

5

FIRST

20

20

1

4

2

5

151-280

SECOND

20

40

4

5

6

7

FIRST

32

32

2

5

3

7

281-500

SECOND

32

64

6

7

8

9

FIRST

50

50

3

7

5

9

501-1200

SECOND

50

100

8

9

12

13

FIRST

80

80

5

9

7

11

1201-3200

SECOND

80

160

12

13

18

19

FIRST

125

125

7

11

11

16

3201-10000

SECOND

125

250

18

19

26

27

AC = Acceptance Number

RE = Rejection Number

(a) Single sampling plan. A single sample

defect class. If an additional sample is required for only

one particular defect class, the inspection of the second

plan, corresponding to the appropriate lot size and

sample will be restricted to only that particular defect

defect classification, is used involving lots of 25 items or

class. For example, if the sampling table indicates

less. A separate sample size and pair of acceptance

acceptance for the Major-A defect class, but requires an

and rejection numbers is shown under the column

additional sample to reach and accept or reject decision

headed Major-A and Major-B. The numbers under the

for Major-B defects, Major-A defectives so observed on

column headed AC refer to the maximum allowable

the second sample will not contribute to lot rejection of

number of defective item(s) in the sample that are

the Major-A defect class. When a rejection number is

permissible for acceptance. Conversely, the numbers

reached in a second stage sample, inspection will be

under the columns headed RE refer to the minimum

discontinued.

number of defective item(s) in the sample required to

(3) Inspection method.

Perform technical

cause rejection of the lot.

(b) Double sampling plan. A double sampling

inspection of the selected samples. Functional or

performance tests should be avoided unless there are

plan, corresponding to the appropriate lot size is used if

significant indications that components of the items

a successive stage cumulative acceptance and rejection

have deteriorated to a degree that operational problems

numbers are indicated. The same sample size is used to

will exist.

determine the acceptance for both Major-A and Major-B

c. Defect Classification. Refer to Appendix II and

defectives. The interpretation of the columns headed by

III for listings of defects and their classifications.

AC and RE is the same as that described for the single

Defects should be classified as critical (when critical

sampling plan in (a) above. If at the first sampling

defects are considered), Major-A, Major-B or Minor,

stage, the number of defective items found is between

even if they are not considered to belong fully in these

the two numbers indicated in the column headed by AC

classes at the time of the inspection, but can reasonably

and RE, an additional sample must be selected to arrive

be expected to be in these classes prior to the next

at an accept or reject decision for only one particular

scheduled inspection period. When inspection or testing

of an item

6