TM 5-2420-230-24-1

5.2 Electrical interface

The EGS is connected with the vehicle wiring through a 15 pole male DSUB connector.

Each EGS application gets its own wiring diagram, describing how to connect these 15 wires to the

vehicle's light system, the transmission control valve and to other outputs and inputs.

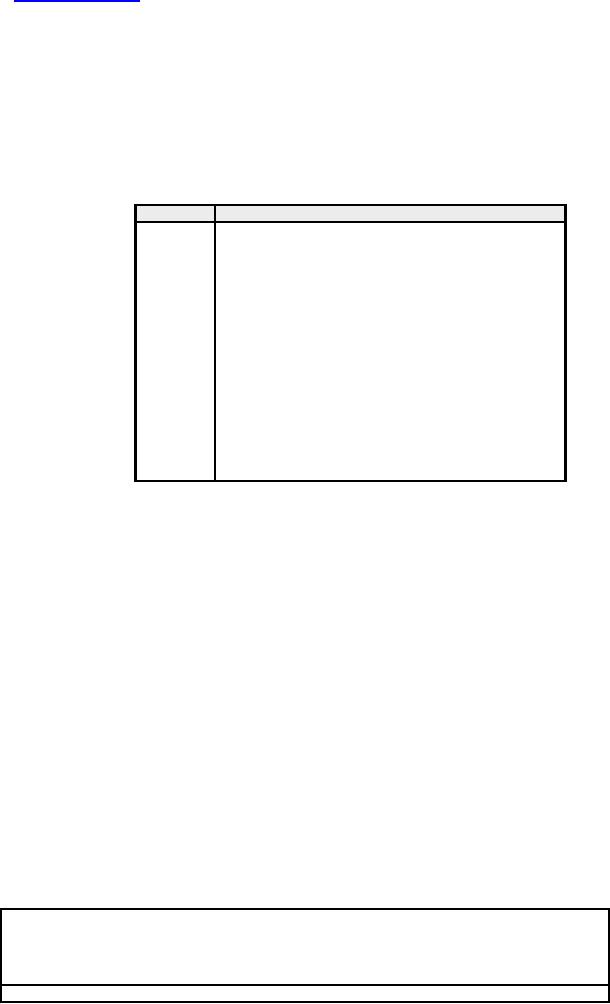

5.2.1 Pin designations

Below table lists the function of each EGS connector pin for an 8 speed transmission :

pin

comment

1

BATTERY PLUS

2

BATTERY GROUND

3

Option dependant output

4

C.V. Solenoid 1

5

C.V. Solenoid 2

6

C.V. Forward solenoid

7

C.V. Reverse solenoid

8

Option dependant output

9

C.V. Solenoid 3

10

Speed sensor input HOT

11

Speed sensor input GND

12

Speed sensor supply 8 Volt / speedometer output

13

C.V. Forward High solenoid

14

Option dependant input

15

Option dependant input

16

Shield ground (internally connected to wire 2)

'C.V.' stands for Control Valve.

5.2.2 Speed sensor mounting

The EGS can support inductive (2 wire), hall-effect (3 wire) and magneto resistive (2 wire) speed

sensors. Speed sensor informs the EGS about the vehicle and the turbine speed.

This information is used to protect the transmission for overspeeding and implementation of various

functions such as automatic lockup, automatic speed sensed shifting, ... etc.

5.2.2.a Inductive sensors

Sensor installation :

Inductive sensors (p/n 4200572, 4200573 & 4200669) generate analogue voltages with

amplitudes ranging from millivolts to several volts (depending on gear speed and sensor

mounting).

The distance from the sensor head to the gear teeth must be smaller than 0.6 mm. This is

accomplished on each transmission in our factory.

EGS user manual. Page 13 of 25

SPICER CLARK-HURTH

Document reference : egsman4.doc

Revision date: 07/04/97

Ten Briele 3, 8200 Brugge, Belgium

Tel: +32/50/402445

Fax: +32/50/402402

G-15