TM 5-2420-230-24-1

When the steering wheel is turned, oil flow is applied to one end of the steering gear piston causing pressure

to build. This pressure causes the piston to move. As the piston moves it is displaced by a volume of oil under

pressure. The speed the piston moves is dependent on the amount of oil flow or,

Flow = Speed of steering.

Maximum system relief pressure limits the amount of steering gear output available to steer your specific vehicle or,

Pressure = The amount of work the steering gear can do.

Keeping the basic formula of "Flow = Steering Wheel Speed" and "Pressure = Work" in mind will help you

diagnose steering problems.

Oil pressure and flow requirements are set during the design of the steering system. When diagnosing steering

problems, oil pressure and flow must meet design specifications. Pressure and flow specifications vary. Follow

the vehicle manufacturer's recommendations.

System back pressure and operating temperature must be considered during the diagnosis of the steering system.

High system back pressure will create heat.

High system oil temperatures reduce overall efficiency of the steering pump and steering gear.

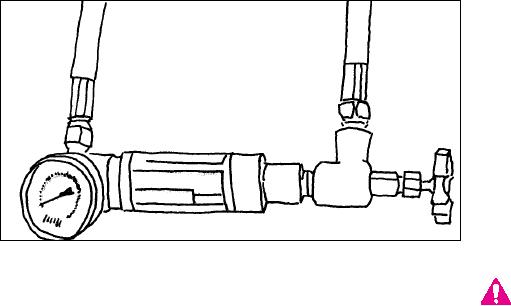

Various types of pressure and flow meters are available to diagnose power steering problems. A pressure gauge

rated at 3000 PSI and a flow meter with a capacity of 10 GPM are needed to check oil pressure and flow.

A shutoff valve placed downstream from the pressure gauge allows the hydraulic supply pump to be isolated

from the gear to check pump relief pressure. A simple thermometer placed in the reservoir will show system

temperature.

Pictured below is the Sheppard Heavy Duty Power Steering Test Kit. This is an excellent tool for troubleshooting

power steering systems and can be ordered using the form in the Miscellaneous section of this manual.

Figure 7

This tester is a self contained, direct

reading device to check system flow,

pressure or both at the same time. It

can detect worn components, check

flow and pressure control settings or

monitor overall system performance.

LOW COST - EASY TO USE

Only one hose connection is broken,

either at the pump output or at the

pressure input to the power steering

gear housing.

Figure 7

WARNING

* Installs between pump and steering gear

OIL UNDER PRESSURE CAN

* Shutoff valve isolates pump from gear

P E N E T R AT E

THE

SKIN

* Pressure and flow can be read at the same time

C AU S I N G SEVERE INJURY.

* 0-3000 P.S.I. pressure gauge

NEVER USE YOUR HANDS TO

* 1-10 G.P.M. flow meter

CHECK FOR LEAKS.

* Complete with hoses & standard swivel fitting

Using a pressure and flow test kit, proceed with the evaluation of the hydraulic system. Record your findings

on the troubleshooting checklist.

K-18