TM 5-2420-230-24-2

General Engine Test Procedures - (Chassis Dynamometer) (14-05)

Section 14 - Engine Testing - Group 14

Page 14-22

B Series Shop Manual

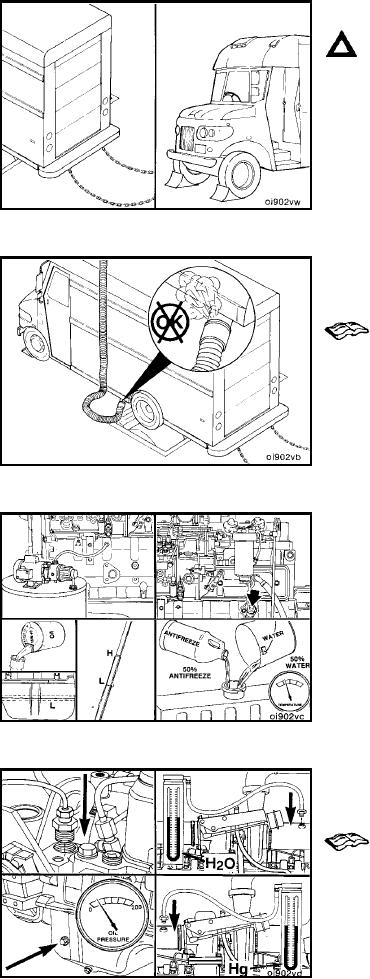

Carefully position the vehicle on the rollers.

Caution: To prevent damage to the chassis dynamom-

eter, there must be some slack in the tension of the

tie-down chains.

Attach the tie-down chains to the rear of the vehicle,

and put wheel chocks in front of the front wheels.

Adjust the vehicle and dynamometer room exhaust

system to make sure all exhaust gases are removed

from the room.

Refer to the chassis dynamometer and vehicle

manufacturer's recommendations and specifica-

tions for testing procedures.

General Engine Test Procedures -

(Chassis Dynamometer) (14-05)

The following procedure assumes that the lubricating oil

and fuel systems were correctly primed, the dipstick cali-

brated, and the engine filled to the correct levels with oil

and coolant during installation of the engine into the chas-

sis. If these sytems were not serviced during installation

of the engine, refer to Engine Dynamometer Test - Instal-

lation of the Engine (14-01) for instructions on priming the

lubricating oil and the fuel systems and calibrating the

dipstick. Refer to the latest B Series Operation and Main-

tenance Manual, Bulletin No. 3810205, for instructions on

filling the lubricating oil and the cooling systems.

The number of instruments and gauges required to per-

form a chassis dynamometer test will vary according to

the type and the capability of the test equipment used.

Refer to pages 14-4 and 14-5 for the correct system pres-

sure and temperature gauge connecting locations.

L-452