TM 5-2420-230-24-2

Section 14 - Engine Testing - Group 14

General Engine Test Procedures - (Chassis Dynamometer) (14-05)

B Series Shop Manual

Page 14-23

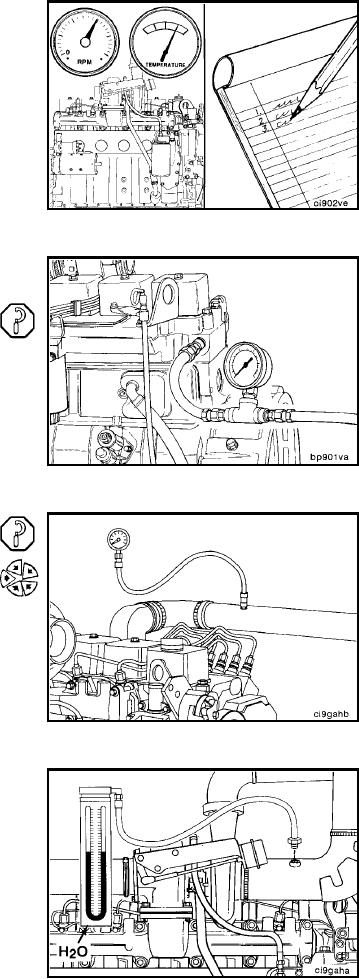

To correctly monitor an engine's performance, record the

following parameters:

Lubricating oil pressure (vehicle instrument panel)

Coolant temperature (vehicle instrument panel)

Coolant pressure

Turbocharger outlet pressure

Exhaust restriction

Intake manifold pressure

Inlet air restriction

Blowby

Engine speed (RPM) (vehicle instrument panel)

Wheel horsepower (WHP) (dynamometer controls)

Measure the coolant pressure at the cylinder head, rear

fuel pump side.

Minimum Gauge Capacity:

415 kPa [60 psi]

Measure turbocharger outlet pressure and intake mani-

fold pressure. The drop in pressure accross the

aftercooler/charge air cooler must not exceed 21 kPa [3

psi].

Connect a water manometer to the turbocharger air inlet

pipe to test air restriction.

NOTE: The manometer connection must be installed at a 90

degree angle to the air flow in a straight section of pipe, one

pipe diameter before the turbocharger.

NOTE: A vacuum gauge can be used in place of the water

manometer.

Minimum Gauge Capacity:

760 mm H20 [30 in. H20]

L-453