TM 5-2420-230-24-2

Section V - Engine Component Specifications - Group 18

Component Specifications and Torque Values

B Series

Page V-21

Component or Assembly (Procedure)

Ref.No./Steps

Metric

U.S.

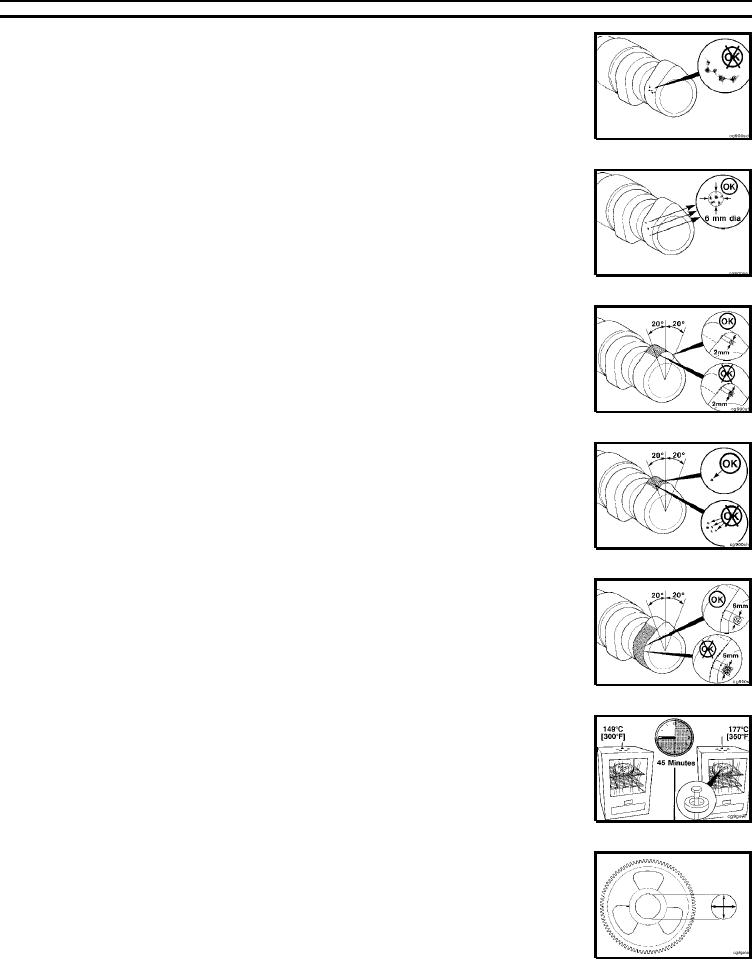

Interconnection of pits is not allowable and is treated as one pit.

The total pits, when added together, should not exceed a circle of 6 mm [0.236 in].

Only one pit is allowed within + or - 20 degrees of the nose of the camshaft lobe.

Edge Deterioration (Breakdown):

The area of edge deterioration should not be greater than the equivalent area of a 2 mm [0.079 in]

circle within + or - 20 degrees of the nose of the camshaft lobe.

Outside of the + or - 20 degrees of the nose of the camshaft lobe, the areas of edge deterioration

should not be greater than the quivalent area of a 6 mm [0.236 in] circle.

Caution: The camshaft gear will be permanently distorted if overheated. The oven tempera-

ture should never exceed 177C [350F].

Heat the camshaft gear for non-bolted 1991 and non-automotive 1994 camshafts in an oven at

149C [300F] for 45 minutes.

Heat the camshaft gear for bolted 1991 camshafts (steel gear) and all 1994 automotive to 177C

[350F].

Camshaft Gear Bore I.D.

41.500 mm

MIN

1.6339 in

41.525 mm

MAX

1.6348 in

L-495