TM 5-2420-230-24-2

B3.9 and B5.9 Series Engines

Crankshaft (001-016)

Section 1 - Cylinder Block - Group 01

Page 1-53

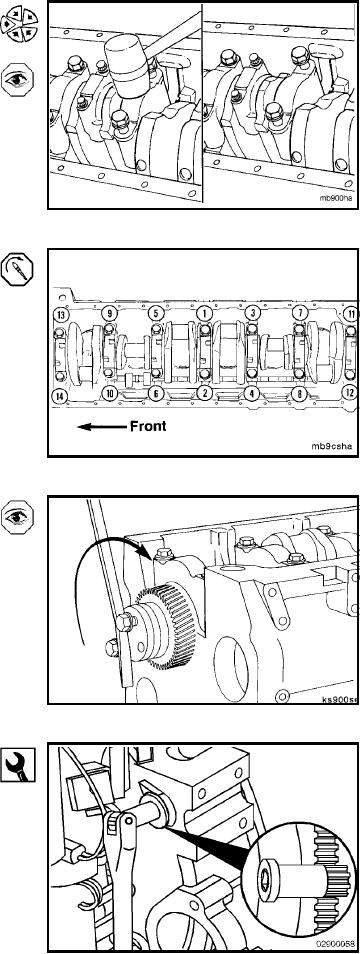

Tap the main bearing cap gently into position.

NOTE: Make sure the main bearing is still aligned with the

cap.

When seated, the main bearing capscrews can be threaded

in by hand.

Tighten the main bearing capscrews evenly following the

illustrated sequence.

Torque Value: Step 1

60 Nm

[44 ft-lb]

2

90 Nm

[66 ft-lb]

3

Turn clockwise 90 degrees

NOTE: The crankshaft must rotate freely after the main

bearings have been installed.

Inspect the main bearing installations and the size of the

main bearings if the crankshaft will not rotate freely.

Rotation Check (001-016-052)

Barring Tool, Part No. 3824591

The barring tool inserts into the flywheel housing and en-

gages the flywheel ring gear. The crankshaft can then be

rotated by hand using a 1/2-inch-drive ratchet or breaker

bar.

L-731