TM 5-2420-230-24-2

Crankshaft (001-016)

B3.9 and B5.9 Series Engines

Page 1-48

Section 1 - Cylinder Block - Group 01

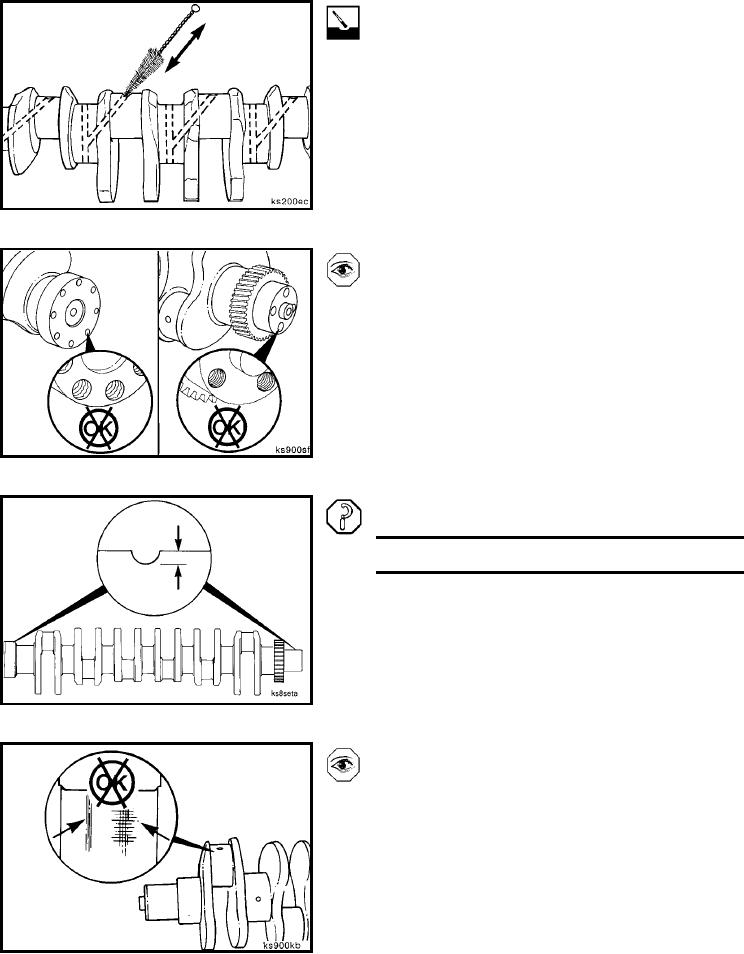

Clean (001-016-006)

Use fine crocus cloth to polish the machined surfaces.

Use a bristle brush to clean the oil drillings.

Inspect for Reuse (001-016-007)

Inspect the threaded capscrew holes for damage.

Use one of the following methods to repair any threaded

holes:

Chase the threads

Use the threaded insert kit, Part No. 3822709.

NOTE: If more than two threaded holes are damaged in one

end, the crankshaft must be replaced.

Measure the front and rear oil seal contact areas for a wear

groove.

Crankshaft Front and Rear Oil Seal Wear Groove

mm

in

0.25

MAX

0.010

Front and rear wear sleeves are available for a crankshaft

that is worn beyond the limit.

Inspect the crankshaft connecting rod and main journals

for deep scoring, overheating, etc.

L-726