TM 5-2420-230-24-2

Connecting Rod (001-014)

B3.9 and B5.9 Series Engines

Page 1-44

Section 1 - Cylinder Block - Group 01

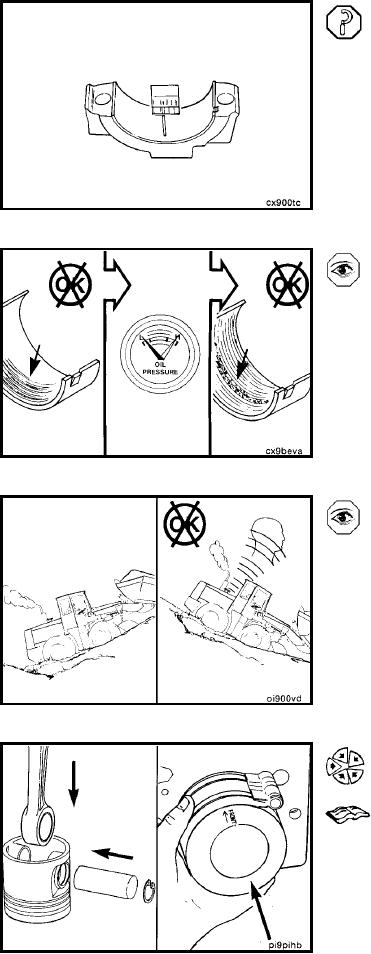

Bearing clearance can also be determined with Plastigauge

during engine assembly.

Test (001-014-012)

Crankshaft and Main Bearings

Improper maintenance of the lubrication system is also the

primary cause of reduced main bearing life.

A malfunction of the crankshaft/main bearing will usually

be detected by reduced lubricating oil pressure. If the rod

bearings continue operation with low-lubricating oil pres-

sure, this will lead to a rapid deterioration of the bearings

and eventually will produce a knocking sound.

A connecting rod knock occurs when the engine is not

loaded. Verify by first applying load and then unloading and

listening for the knock.

Install (001-014-026)

Install the pistons and connecting rod assemblies. Refer to

Procedure 001-054.

L-722