TM 5-2420-230-24-2

B3.9 and B5.9 Series Engines

Connecting Rod (001-014)

Section 1 - Cylinder Block - Group 01

Page 1-43

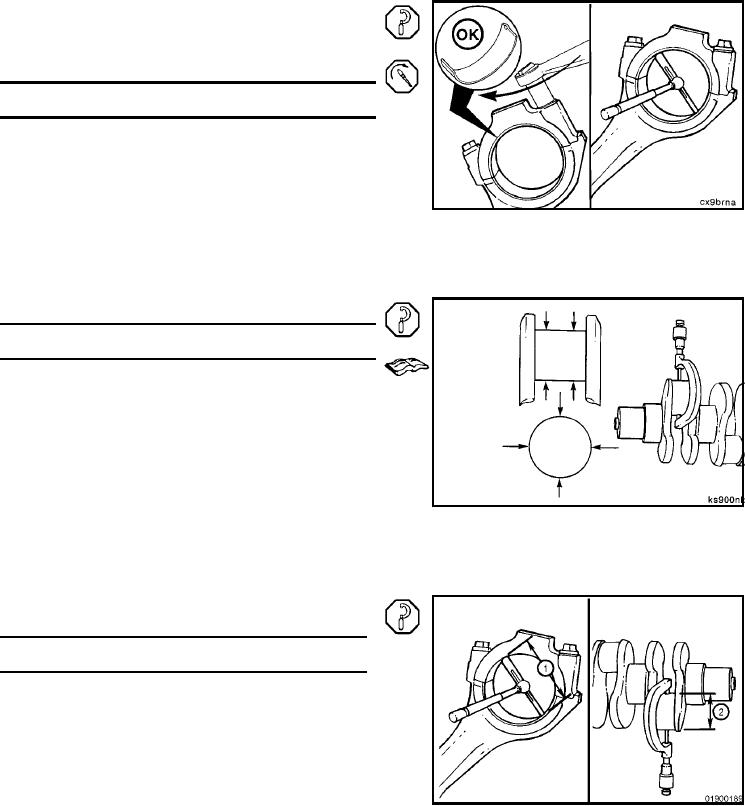

Measure the connecting rod crankshaft bore inside diam-

capscrews.

Torque Value: 100 Nm

[74 ft-lb]

Connecting Rod Bore Diameter (Bearings Installed)

mm

in

Standard

69.051

MIN

2.7185

69.103

MAX

2.7205

0.25 mm Oversize

68.801

MIN

2.7087

68.853

MAX

2.7107

0.50 mm Oversize

68.551

MIN

2.6989

68.603

MAX

2.7009

0.75 mm Oversize

68.301

MIN

2.6890

68.353

MAX

2.6911

1.00 mm Oversize

68.051

MIN

2.6792

68.103

MAX

2.6812

Measure the diameter of the rod journal on the crankshaft.

Crankshaft Rod Journal

Diameter

mm

in

Standard

68.962

MIN

2.7150

69.012

MAX

2.7170

0.25 mm Undersize

68.712

MIN

2.7052

68.762

MAX

2.7072

0.50 mm Undersize

68.462

MIN

2.6953

68.512

MAX

2.6973

0.75 mm Undersize

68.212

MIN

2.6855

68.262

MAX

2.6875

1.0 mm Undersize

67.952

MIN

2.6753

69.012

MAX

2.7170

NOTE: If crankshaft rod journals are not within the given

specifications, the crankshaft must be removed and

reground.

Bearing clearance equals rod inside diameter (with bear-

ing)(1) minus the crankshaft journal diameter (2).

Bearing Clearance

mm

in

0.038

MIN

0.0015

0.116

MAX

0.0046

L-721