TM 5-2420-230-24-2

Turbocharger Wastegate Actuator (010-050)

B3.9 and B5.9 Series Engines

Page 10-48

Section 10 - Air Intake System - Group 10

Test (010-050-012)

Functional Check

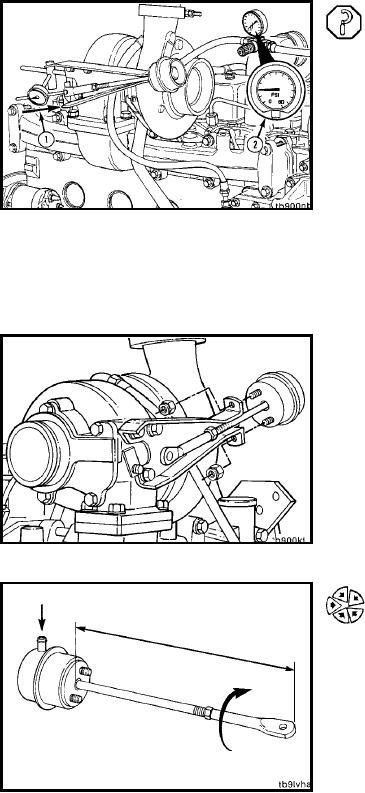

Attach a dial indicator as shown, so that its shaft is in line

with the wastegate actuator rod. Set the indicator to zero,

with no air pressure applied to the wastegate capsule.

Connect clean, regulated air pressure and a pressure gauge

to the capsule. Apply air pressure to make sure the

wastegate is functioning properly.

Air Pressure:

200 kPa

[29 psi]

The rod should move without any sticking or air leakage.

Rod:

0.33 to 1.27 mm

[0.013 to 0.050 in]

NOTE: No air should be heard leaking through a functional

wastegate capsule.

NOTE: A small amount of travel when air pressure is first

applied is normal; the tolerance is being removed from the

system.

Replace the actuator if no movement of the actuator rod

and lever is detected.

Install (010-050-026)

Install the adjusting link end onto the boost capsule act-

uator assembly. Adjust the rod to approximately the same

length as when removed.

L-1172