TM 5-3805-280-10

Safety

be ready to activate the cabin emergency stop if need

be.

communication must be established in a reli-

S

able manner.

Make sure any hand signal will be perfectly

understood.

the operator must make sure the following

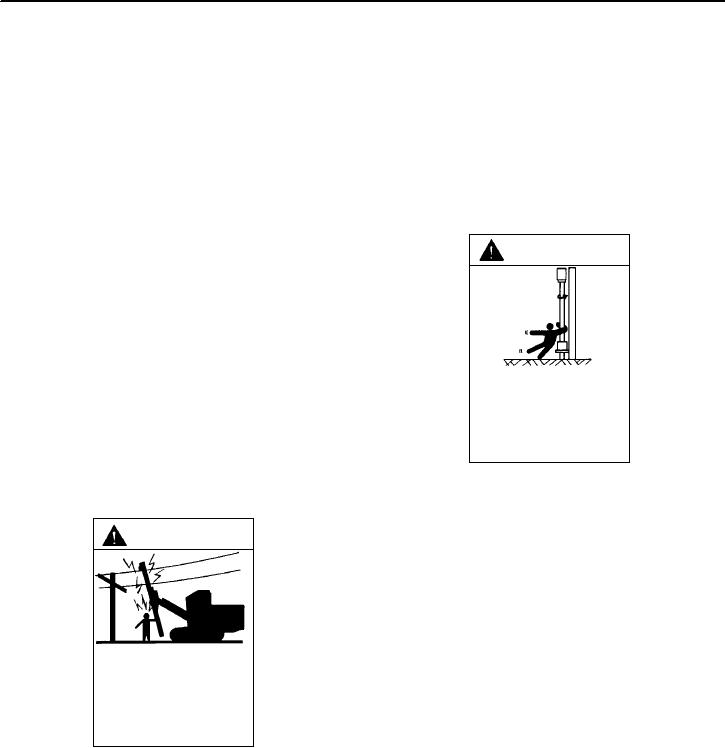

S

safety decal is affixed on the drill guide to warn the

service man of risks incurred.

8

6 N0 /

N

Before starting work, the operator will make sure

there are no buried electrical, gas, water or other

Moving parts can caus svr

pipes or lines.

injury or dath.

Always kp clar of moving drill,

Always be aware of previously drilled holes, and

fd chain, hoss and drill stl

systm.

where they are located : any open hole can cause se-

vere injury to the operator or someone else. The loss

the service man must be informed about the

S

of tools, drill rods, drill bits or any other item can occur.

use of the emergency stop mounted on the guide.

Always have the cabin door closed and the dust

8

6 N0 /

N

collector running when drilling to prevent respiratory

damage.

Keep all work areas clean and orderly.

ROCK DRILL MAINTENANCE

Keep hands, arms, legs and clothing away from

Shock hazard will caus svr injury

or dath.

moving or rotating parts.

Do not position any part of machin

within 28 ft. (7,9 m/ of any lctric

Only use genuine replacement parts.

powr lin.

Stopping the drill for mainte-

When rising the guide, take care of any overhead

lines.

nance or bit change etc...

Always maintain a minimum distance of 25 Ft.

Prior to leaving the operators compartment, the

(7.6 m) distance between the machine and any

excavators hydraulic safety arm must be raised to

overhead lines during any operation.

lock in the machines safety switch. This renders all

controls inoperable thus preventing any unwanted

The operator will make sure that everybody

movement.

stands clear from the machine in operation and stays

at a distance of 7 meters (25 ft.).

Hydraulic cylinder

Nevertheless, some operations may need people

to enter the restricted area (checking of coupling tem-

The hydraulic cylinder is equipped with 2 load

perature during feed thrust adjustment for instance).

sustaining valves.

On such an occasion :

The loadsustaining valves allow the disconnect-

the operator must supervise, from the cabin,

ing of the hydraulic hoses from the cylinder if they

S

the safety of the service man doing the work. He must

need to be changed. But :

1-24