TM 5-3805-280-24-1

Torque Values

9000

SERVICE RECOMMENDATIONS FOR

03

9

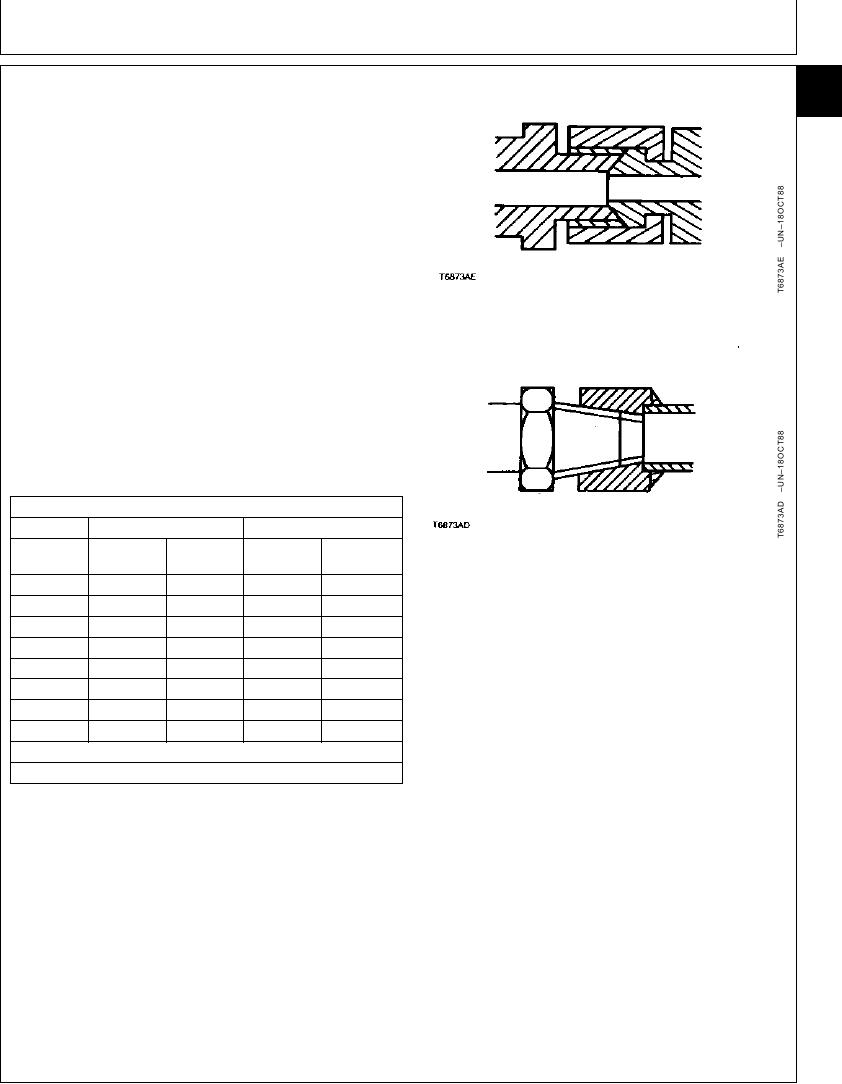

FLARED CONNECTIONS--STRAIGHT OR

TAPERED THREADS

1. Inspect flare and flare seat. They must be free of dirt

or obvious defects.

2. Defects in the tube flare cannot be repaired.

Overtightening a defective flared fitting will not stop

leaks.

3. Align the tube with the fitting before attempting to start

Straight Thread

the nut.

4. Lubricate the male threads with hydraulic fluid or

petroleum jelly.

5. Index angle fittings and tighten by hand.

6. Tighten fitting or nut to torque value shown on the

chart. Do not allow hoses to twist when tightening

fittings.

TORQUE CHARTa

Straight Threadb

Tapered Thread

Tapered Thread

Thread

Size

Nm

lb-ft

Nm

lb-ft

1/8

15

11

1/4

20

15

45

33

3/8

29

21

69

51

1/2

49

36

93

69

3/4

69

51

176

130

1

157

116

343

253

1-1/2

196

145

539

398

2

255

188

588

434

Torque tolerance is 10%.

a

b

With seat face.

NOTE: If female thread is cast iron (control valves, brake

valves motors, etc.), torque must be reduced

approximately 10%.

04T,90,M171

1928JAN921/1

1-28