TM 5-3805-280-24-1

Torque Values

9000

SERVICE RECOMMENDATIONS FOR INCH SERIES FOUR BOLT FLANGE FITTINGS

03

10

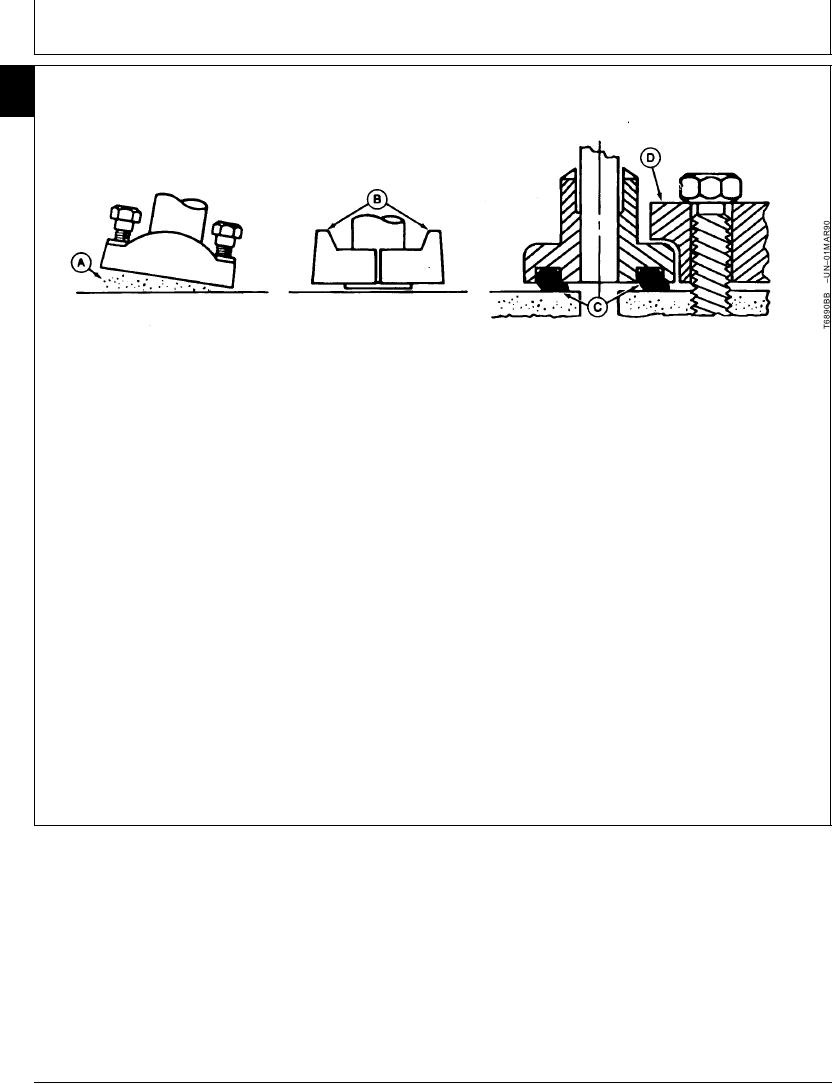

A--Sealing Surface

B--Split Flange

C--Pinched O-Ring

D--Single Piece Flange

must be centrally located on port. Hand tighten cap

1. Clean sealing surfaces (A). Inspect. Scratches

screws to hold flange in place. Do not pinch O-ring.

cause leaks. Roughness causes seal wear.

Out-of-flat causes seal extrusion. If defects cannot

5. Tighten one cap screw, then tighten the diagonally

be polished out, replace component.

opposite cap screw. Tighten two remaining cap

screws. Tighten all cap screws as specified in the

2. Install O-ring (and backup washer if required) into

chart below.

groove using petroleum jelly to hold it in place.

DO NOT use air wrenches. DO NOT tighten one

3. Split flange: Loosely assemble split flange (B)

cap screw fully before tightening the others. DO

halves. Make sure split is centrally located and

NOT over tighten.

perpendicular to port. Hand tighten cap screws to

hold parts in place. Do not pinch O-ring (C).

4. Single piece flange (D): Place hydraulic line in

center of flange and install cap screws. Flange

Continued on next page

04T,90,K174

1901AUG941/2

1-29