TM 5-3805-280-24-1

Adjustments

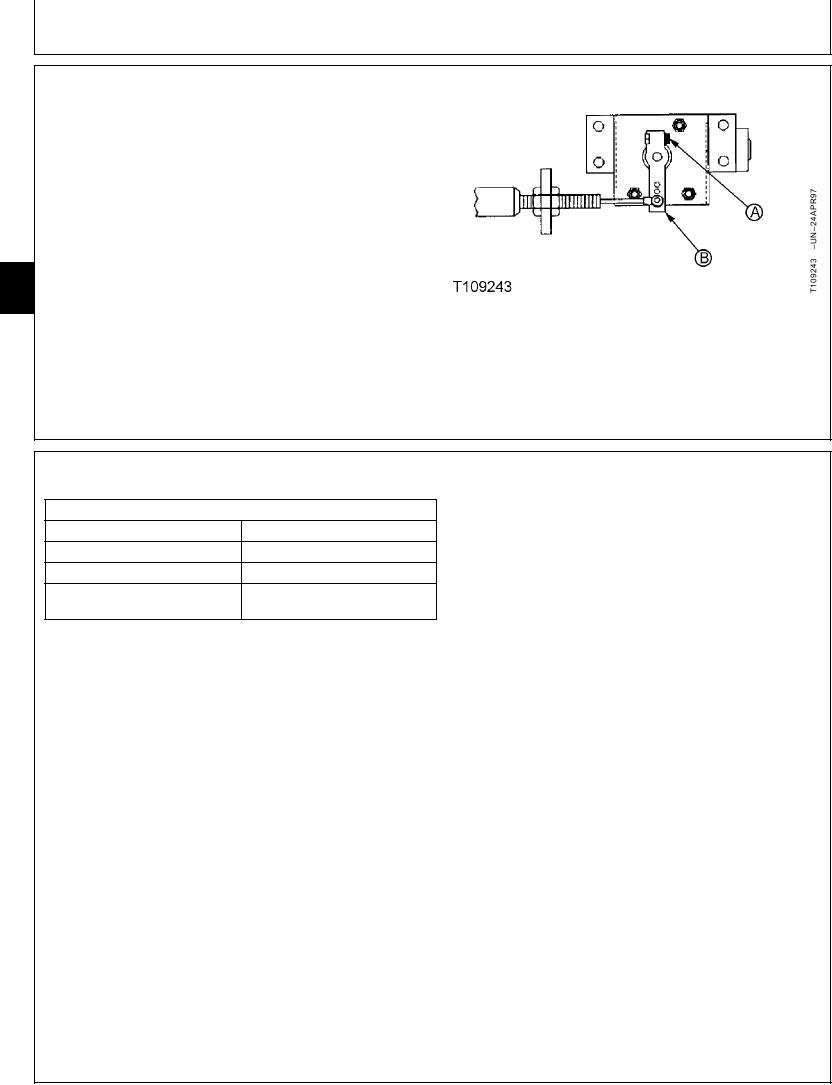

4. Check that engine speed control cable is connected to

the outer hole of engine control motor arm (B).

5. Loosen cap screw (A) in arm (B).

6. Adjust the arm on the shaft so injection pump lever just

contacts the slow idle stop screw.

7. Tighten cap screw (A).

Arm-to-Engine Control Motor Shaft Cap Screw--Specification

9010

20

Torque .......................................................................... 13 Nm (115 lb-in.)

10

A--Cap Screw

8. Do the Engine Speed Learning Procedure. (See

B--Arm

procedure in this group.)

TX,9010,UU3407 1919MAY983/3

ENGINE SPEED LEARNING PROCEDURE

SPECIFICATIONS

900 25 rpm

Engine Slow Idle Speed

1200 25 rpm

Engine Auto-Idle Speed

1980 25 rpm

E (Economy) Mode Speed

2180 25 rpm

Fast Idle in Standard Mode

Speed

When the following components are repaired or replaced,

or when engine speeds deviate from specification, the

engine control motor adjustment and engine learning

control procedure must be performed.

Engine

Engine speed control cable

Engine control motor and sensor

Engine and pump controller

Fast and slow idle stop screws

1. Stop the engine.

2. Disconnect the laptop computer from the test

connector.

Wait for 5 seconds.

Continued on next page

TX,9010,UU3409 1911AUG981/2

3-49