TM 5-3805-280-24-1

Sub-System Diagnostics

ENGINE SPEED (N)

Turn key switch OFF.

YES: Sensor is OK. Go

SENSOR (B16) CHECK

to next check.

Disconnect harness from engine speed sensor.

NO: Sensor has failed.

Measure resistance across speed sensor connector pins

Replace.

1 and 2.

Does ohmmeter read 810 240 ohms?

T7502BM

UN01APR91

Start engine.

Measure AC voltage at speed sensor terminals. Increase

engine speed.

Does AC voltage increase as engine speed increases?

9015

15

76

1/1

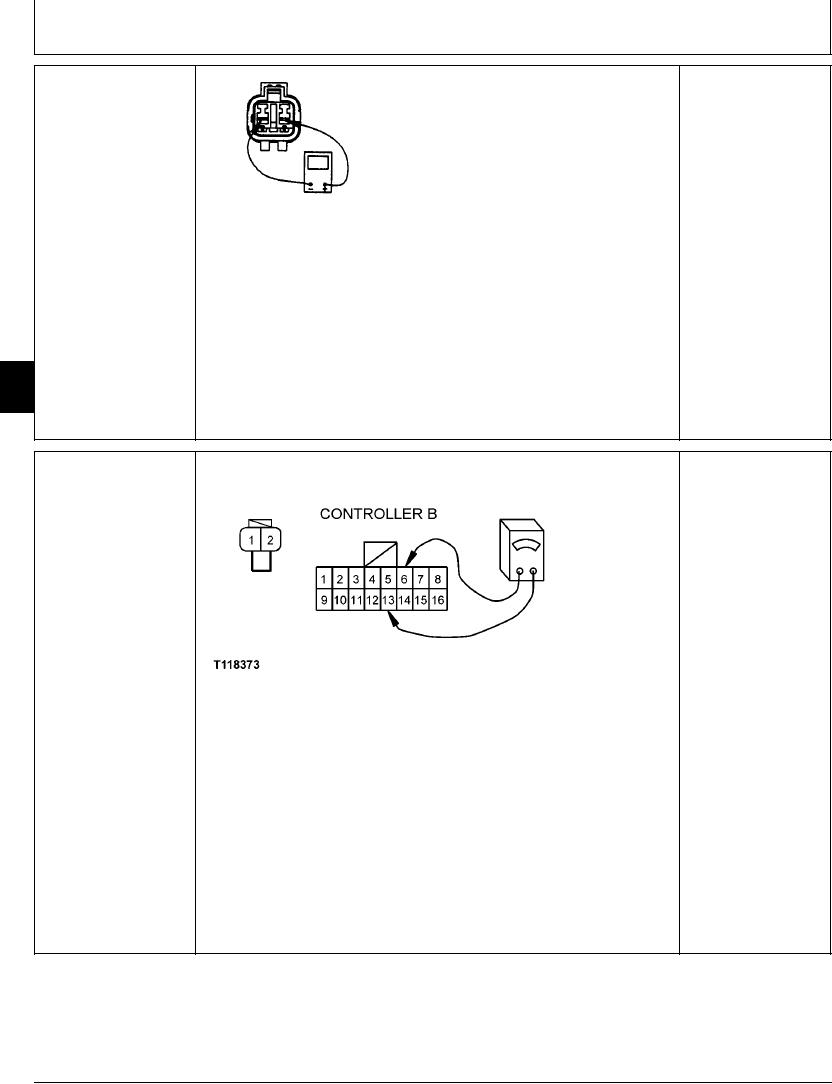

ENGINE SPEED (N)

YES: Harness is OK.

SENSOR (B16)

HARNESS CHECK

NO: Harness has failed.

Repair.

T118373 1930NOV98

Turn key switch OFF.

Disconnect harness from engine speed sensor.

Disconnect 16-pin connector B from engine and pump controller.

Measure continuity between pins 6 and 13 of connector B.

Does ohmmeter read open?

Connect jumper wire between sensor harness connector pins 1 and 2.

Is continuity measured?

1/1

4-141