TM 5-3805-280-24-1

Sub-System Diagnostics

YES: Engine rpm dial

ENGINE RPM DIAL (R10)

harness is OK.

HARNESS CHECK

NO: Harness had failed.

Repair.

9015

15

80

T118397 1930NOV98

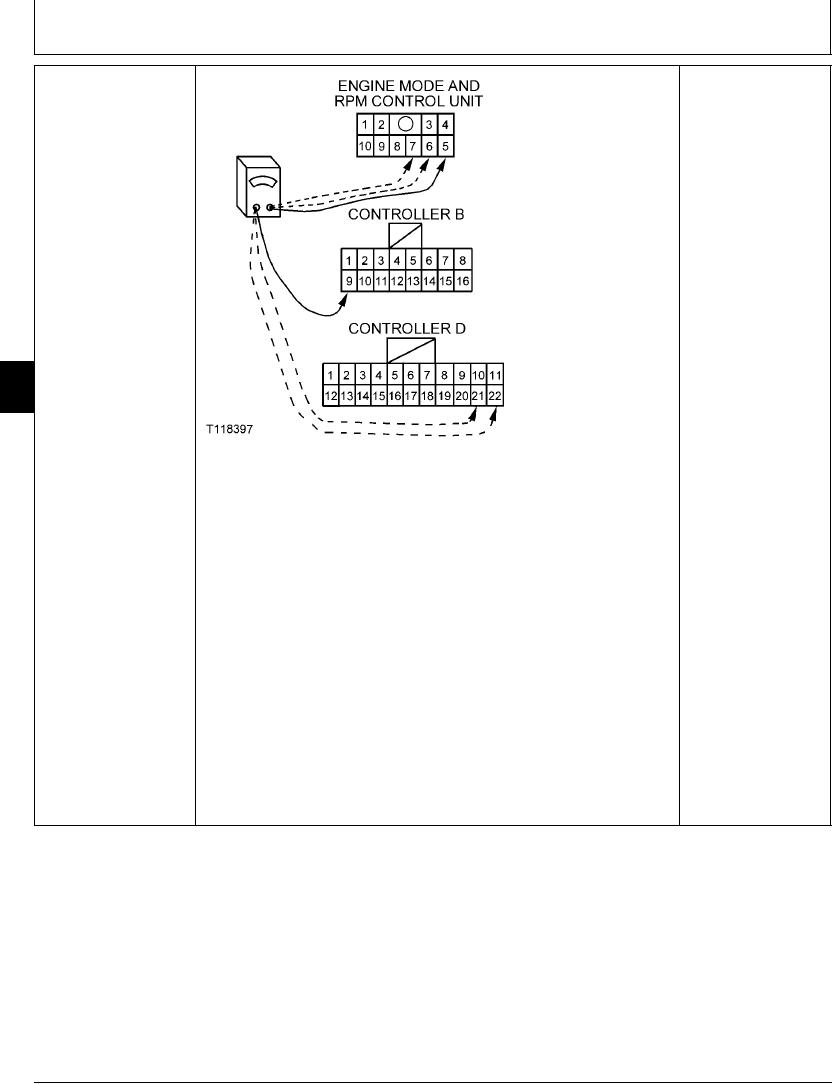

Disconnect 16-pin harness connector B and 22-pin harness connector D from engine

and pump controller.

Disconnect harness connector from engine mode and RPM control unit A4.

Measure continuity from pin 5 of engine mode and RPM control unit harness connector

to pin 9 of engine and pump controller harness connector B.

Measure continuity from pin 7 of engine mode and RPM control unit harness connector

to pin 22 of engine and pump controller harness connector D.

Measure continuity from pin 6 of engine mode and RPM control unit harness connector

to pin 21 of engine and pump controller harness connector D.

Is continuity measured?

1/1

4-145