TM 5-3805-280-24-1

Sub-System Diagnostics

YES: Wire harness is OK.

Go to next check.

NO: Wire from pin 18 of

connector D to pin 2 of

sensor harness connector

has failed. Repair.

9015

15

T118358 1921NOV98

83

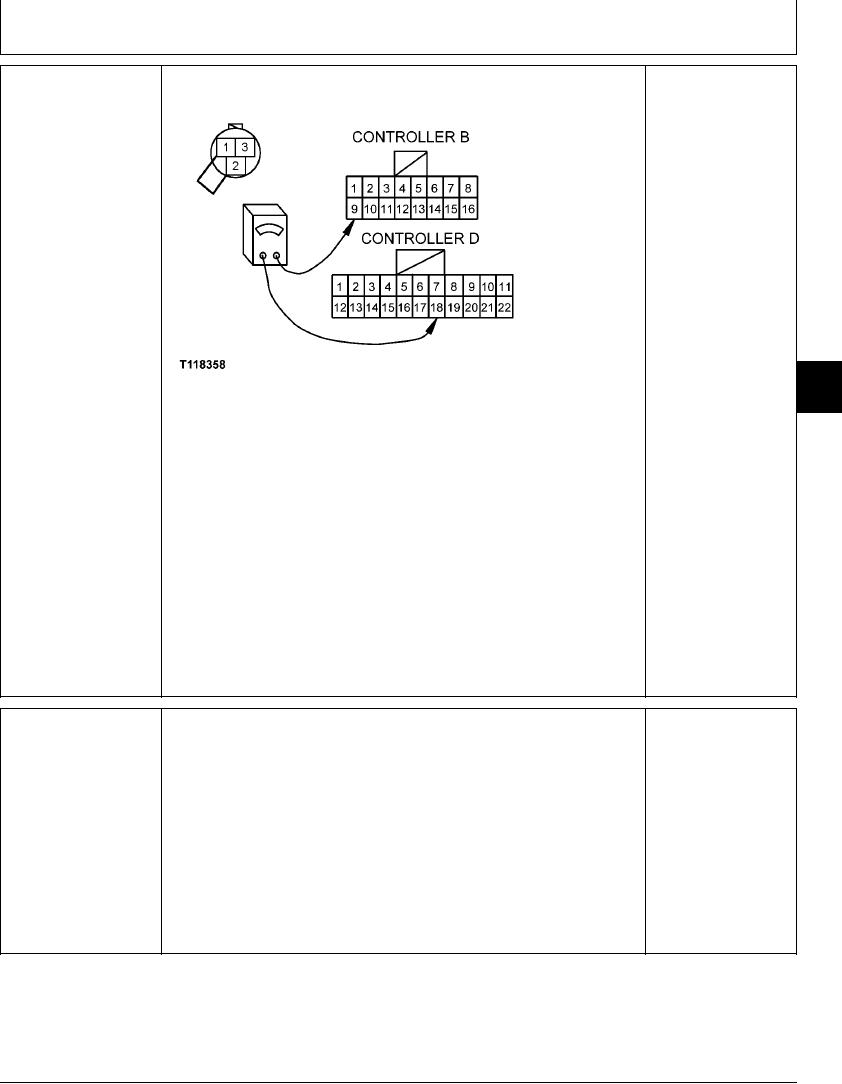

Install jumper between sensor harness connector pins 1 and 2.

Disconnect 22-pin connector D and 16-pin connector B from engine and pump

controller.

Measure continuity between pin 9 of harness connector B and pin 18 of harness

connector D.

Is continuity measured?

2/2

ARM IN PRESSURE

Install pump control test harness JT07353 in series with wiring harness and sensor.

YES: Sensor is OK.

SENSOR (B20) CHECK

Engine and pump

Connect voltmeter to test harness jacks.

controller may have

failed.

With engine running, pilot control lever forward, and hydraulic functions in neutral,

observe voltage.

NO: Sensor has failed.

Replace.

Is voltage between 0.5 and 0.7 volts?

Actuate arm in to achieve hydraulic function over relief.

Does voltage increase to between 3.3 and 3.5 volts with hydraulic function over relief?

1/1

4-148