TM 5-3805-280-24-1

Tests

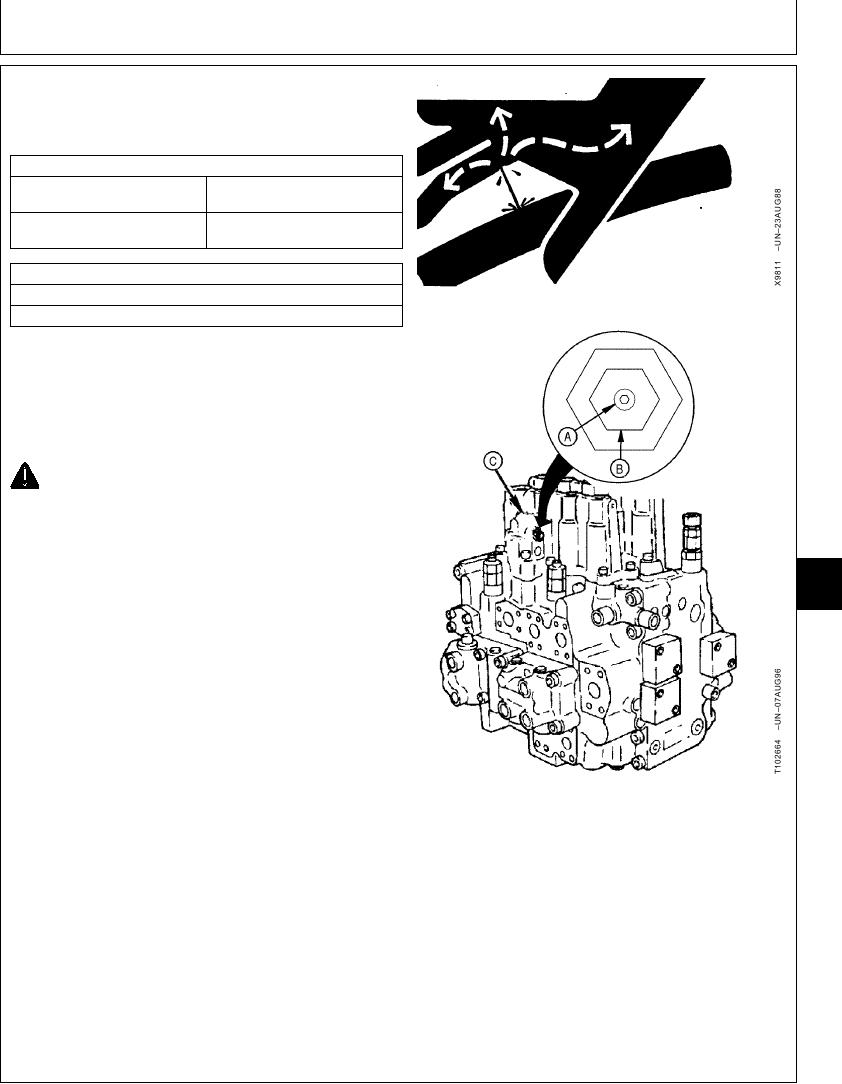

LOWER BOOM WITH ENGINE STOPPED

(WHEN NOT EQUIPPED WITH BOOM

CYLINDER LOAD LOWERING VALVE)

SPECIFICATIONS

Boom Manual Lower Screw

6.9 Nm (60 lb-in.)

Boom Manual Lower

13 Nm (115 lb-in.)

Screw-to-Housing Nut Torque

SERVICE EQUIPMENT AND TOOLS

4 mm Hex Key Wrench

13 mm Combination Wrench

When an engine stops during operation, the boom cannot

be lowered using the pilot controller because there is no

pilot pressure oil to move the boom valve spool.

1. Remove the control valve access cover.

CAUTION: To avoid injury from escaping fluid

under pressure, never loosen screw more than

two turns as screw may come out. Tighten

screw and nut before applying pressure.

Prevent possible injury from unexpected

9025

machine movement. Clear all persons from the

25

area before lowering the boom with the engine

39

stopped.

2. Loosen the small nut (B) on the boom reduced leakage

valve housing (C).

Slowly loosen boom manual lower screw (A) 1/2 turn

using a 4 mm hex key wrench. The boom will start to

lower.

The boom lowering speed can be increased somewhat

Boom Manual Lower Screw

by loosening screw an additional 1-1/2 turns. Never

loosen screw more than two turns.

A--Boom Manual Lower Screw

B--Small Nut

C--Boom Reduced Leakage Valve Housing

3. After bucket is lowered to the ground, tighten the screw

to specification, and then the nut.

Continued on next page

CED,OUOEBAS,9 1925JAN001/2

6-169