TM 5-3805-280-24-1

Tests

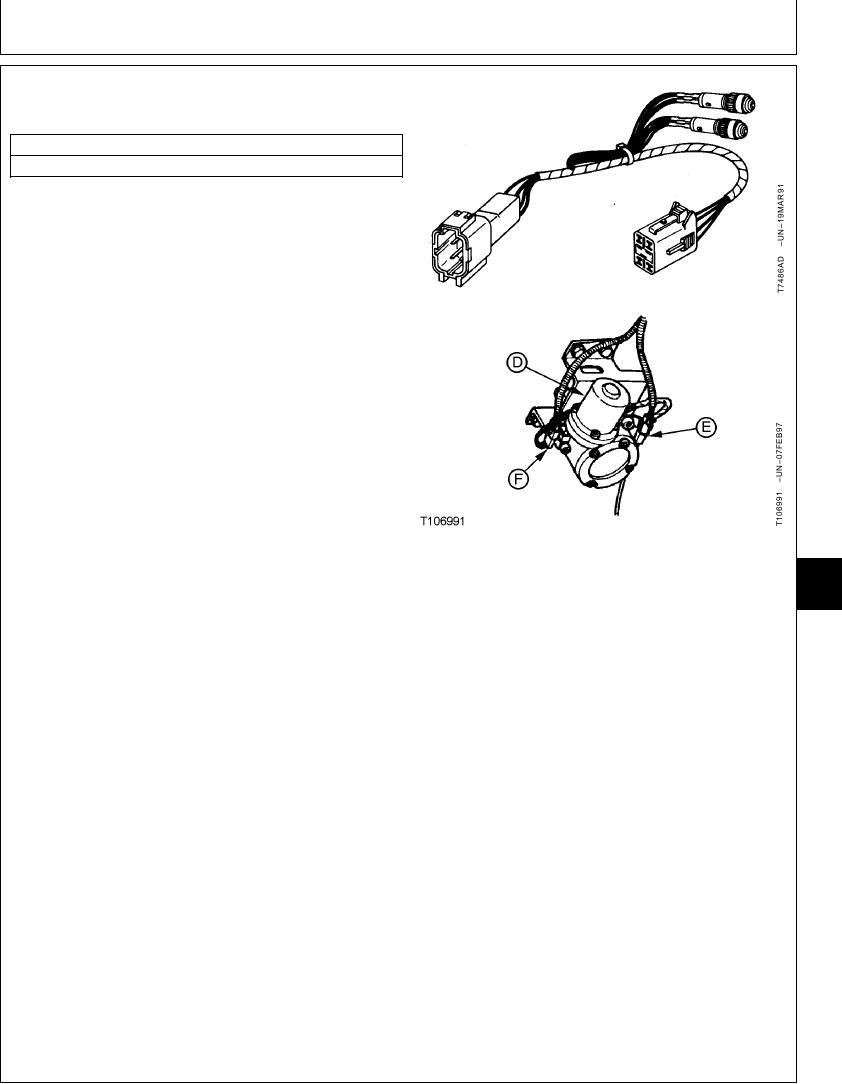

ENGINE CONTROL MOTOR (EC MOTOR)

HARNESS TESTS

ESSENTIAL TOOLS

JT07065 Test Harness

The purpose of test is to check continuity of EC motor

wiring harness (F) and there is a signal from engine and

pump controller (EPC).

NOTE: The laptop computer with excavator diagnostics

program can be used to check the electrical signal

from the engine and pump controller to the engine

control motor. Select "15 EC motor position" from

Monitor Data Items. Typical readings are 72--76

steps at slow idle to 525--550 steps at fast idle.

The readings can vary from machine to machine.

What to look for is that the readings change when

the engine rpm dial is turned, and the E mode,

HP mode, or auto-idle mode is actuated.

IMPORTANT: Disconnecting electrical connectors

while engine is running or with key

switch on can damage engine and

pump controller or other electrical

components.

D--Engine Control Motor

9025

E--Engine Control Sensor Wiring Harness

1. Stop engine. Turn key switch to OFF.

25

F--Engine Control Motor Wiring Harness

51

IMPORTANT: Retainer tab on male half of wiring

harness connector halves must be

pushed down before pulling halves

apart. Never pull on wiring leads.

2. Push retainer tab down then pull connector halves

apart.

3. Install test harness in series with the engine control

motor wiring harness (F).

4. Turn key switch to ON.

5. While observing test indicator lights,

a. Turn engine rpm dial from slow idle to fast idle,

Continued on next page

TX,25,GG2223

1913AUG981/2

6-182