TM 5-3805-280-24-2

Engine System Operation and Tests

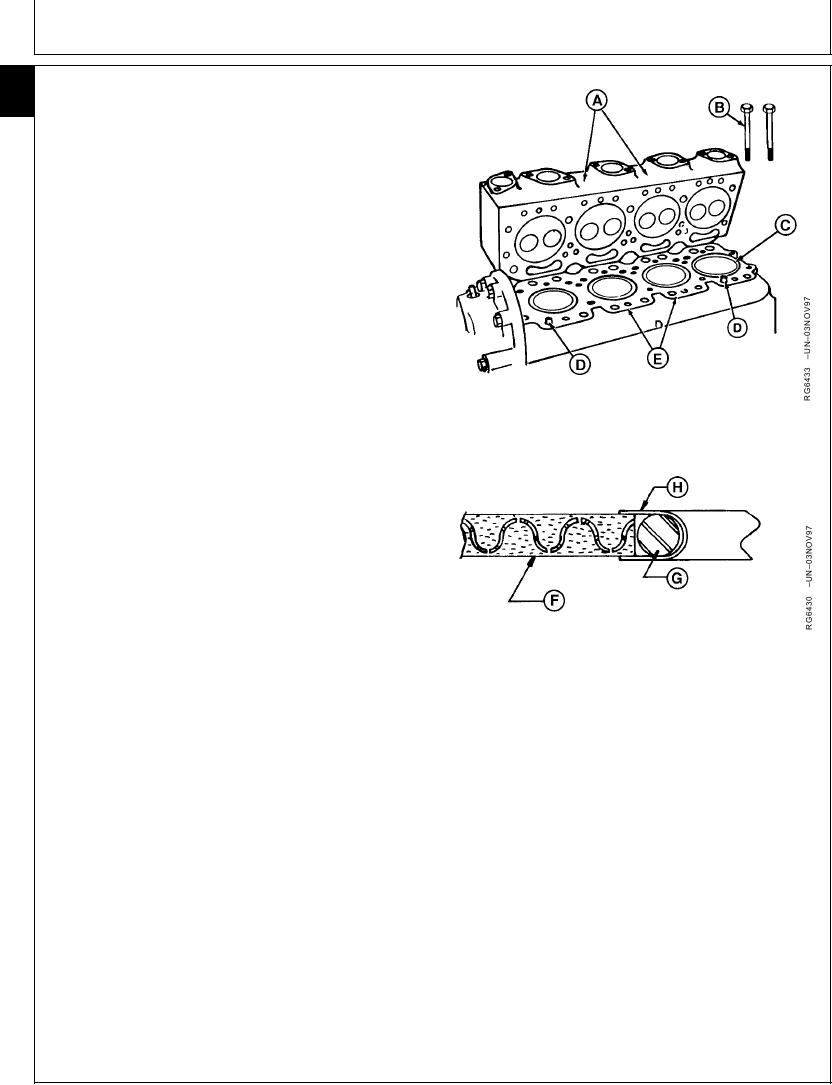

HEAD GASKET JOINT CONSTRUCTION AND

105

10

OPERATION

The head gasket joint consists of the following

components:

Cylinder

head gasket

Cylinder

head (A)

Cylinder

block (E)

Cylinder

liners (C)

Cylinder

head cap screws (B)

The head gasket must form an air-tight seal between

cylinder liners and cylinder head that can withstand the

temperatures and pressures of the combustion process.

The gasket must also form a liquid-tight seal between the

cylinder head and cylinder block to retain coolant and oil

in their respective passages. The gasket is constructed of

thin, formed sheets of steel-inserted, non-asbestos

material (F). The surface of gasket is treated to improve

liquid sealing and anti-stick characteristics. A fire ring

combustion seal (G) is located at each cylinder bore and

is held in place by a U-shaped stainless steel flange (H).

The cylinder head and block must be flat to provide an

even clamping pressure over the entire surface of gasket,

and must have the proper surface finish to keep gasket

material from moving in the joint. Dowels (D) are used to

properly locate head gasket on block.

The cylinder liners must protrude evenly from top of

cylinder block the specified amount to provide adequate

A--Cylinder Head

clamping force on fire ring of each cylinder.

B--Cylinder Head Cap Screws

C--Cylinder Liners

The cap screws must be proper length, made of proper

D--Dowel Pins

E--Cylinder Block

material, and be tightened to proper torque in order to

F--Gasket Body

provide an adequate clamp load between other joint

G--Fire Ring Combustion Seal

components.

H--Stainless Steel Flange

Each of the above components contributes to the integrity

of the head gasket joint. If any of these components do

not conform to specifications, gasket joint may fail

resulting in combustion leaks, coolant leaks, or oil leaks.

Continued on next page

RG,105,JW7658

1921NOV971/2

13-487