TM 5-3805-280-24-2

Air Intake and Exhaust System Operation and Tests

110

through a heat exchanger before it enters the engine.

Exhaust (E), drives the turbocharger to deliver a larger

5

The heat exchanger uses no liquid coolant but relies

quantity of air to meet the engine requirements than

on air flow to cool the charge air.

what could be delivered under naturally aspirated

(non-turbocharged) conditions.

On some engines, an air-to-air aftercooler cools the

turbocharger compressor discharge air by routing it

RG,110,JW7673 1924NOV972/2

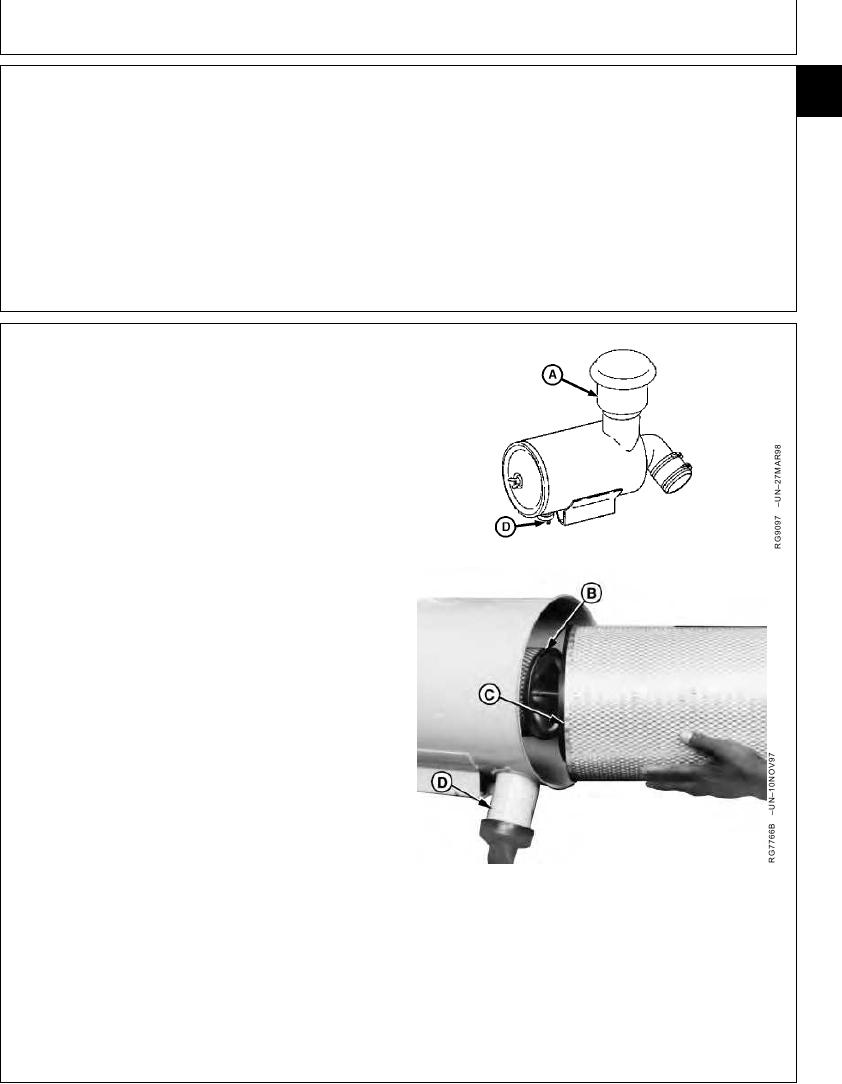

AIR CLEANER OPERATION

Under suction generated by the engine, unfiltered air flows

through air inlet tube (A) and is forced into a high-speed

centrifugal motion by tilted fins in the element. By this

circulating action most of the dust and dirt particles are

separated from the air and collected in the dust unloading

valve (D).

The remaining dirt is removed as the air flows through the

primary element (C) and the secondary (safety) filter (B)

before being drawn into the engine.

The secondary (safety) filter ensures that should primary

element fail, no unfiltered air is drawn into the engine.

A--Air Inlet Tube

B--Secondary (Safety) Filter

C--Primary Element

D--Dust Unloading Valve

RG,110,JW7672 1924NOV971/1

13-511