TM 5-3805-280-24-2

Air Intake and Exhaust System Operation and Tests

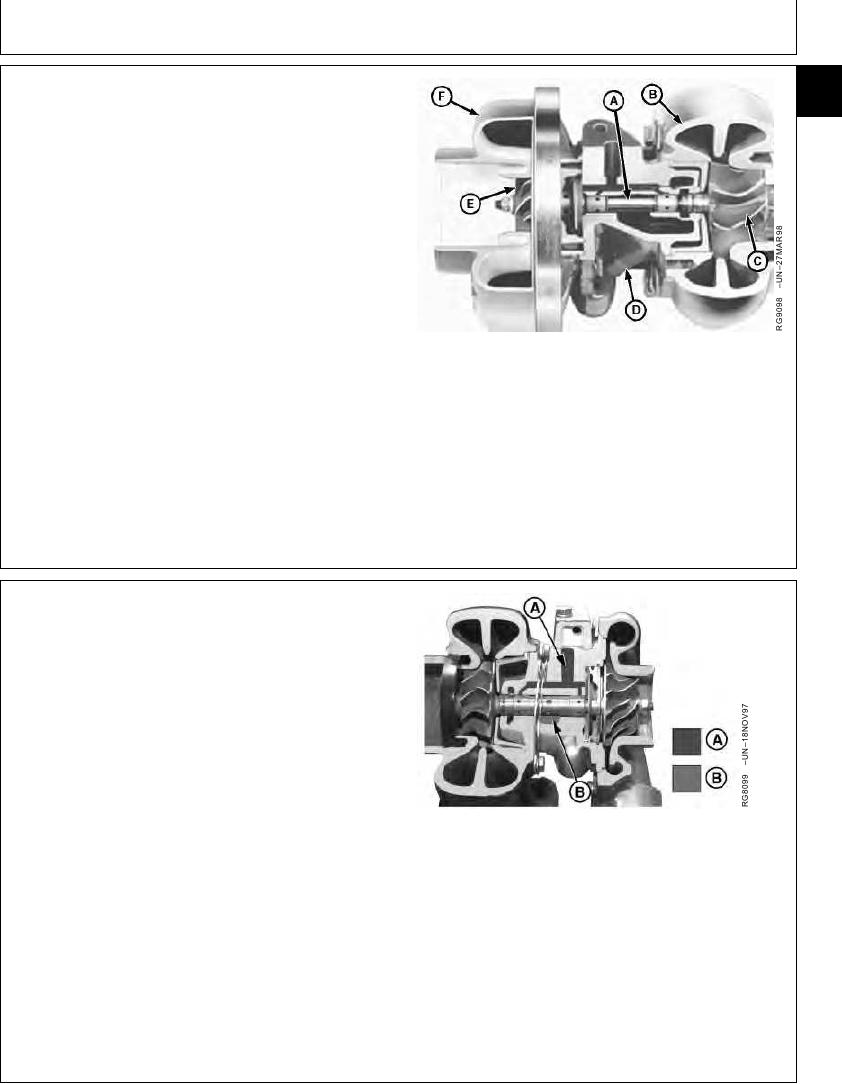

TURBOCHARGER OPERATION

110

11

The turbocharger, which is basically an air pump that is

driven by exhaust gases, allows the engine to produce

added power without increasing displacement.

Turbochargers are specially matched for the power ratio

requirements of each specific application.

The turbine wheel (C) is driven by the hot engine exhaust

gases. These gases flowing through the turbine housing

(B) act on the turbine wheel causing shaft (A) to turn.

Compressor wheel (E) brings in filtered air and discharges

the compressed air into the intake manifold where it is

then delivered to engine cylinders.

A--Shaft

B--Turbine Housing

Engine oil under pressure from the engine lubrication

C--Turbine Wheel

system is forced through passages in center housing (D)

D--Center Housing

to bearings.

E--Compressor Wheel

F--Compressor Housing

RG,110,JW7669 1924NOV971/1

HOW THE TURBOCHARGER IS LUBRICATED

Engine oil under pressure from the engine lubrication

system is pumped through a passage in the bearing

housing and directed to the bearings, thrust plate, and

thrust sleeve. Oil is sealed from the compressor and

turbine by a piston ring at both ends of the bearing

housing.

The turbocharger contains two floating bearings. These

bearings have clearance between the bearing OD and the

housing bore as well as clearance between the bearing ID

and the shaft OD. These clearances are lubricated by the

A--Pressure Oil

oil supply (A) and the bearings are protected by a cushion

B--Discharge Oil

of oil. Discharge oil (B) drains by gravity from the bearing

housing to the engine crankcase.

RG,110,JW7668 1924NOV971/1

13-517