TM 5-3805-280-24-2

Fuel System Operation and Tests

115

39

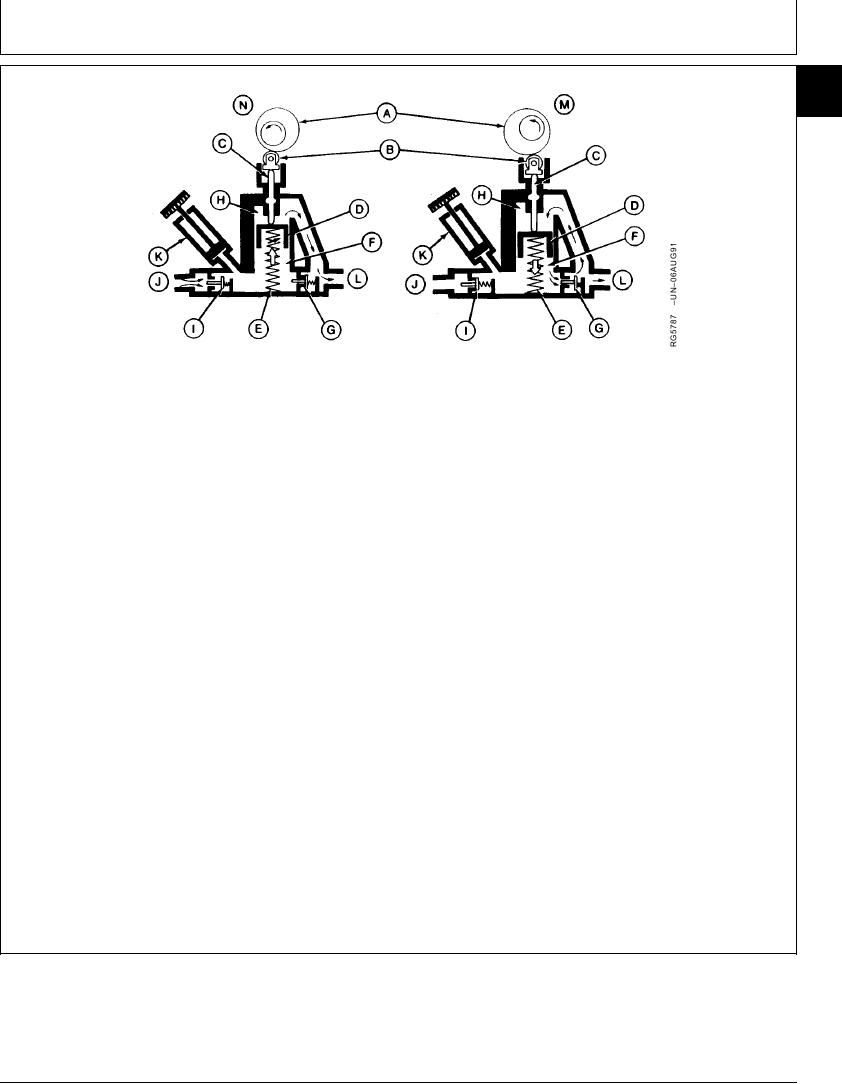

A--Camshaft

E--Plunger Spring

I--Suction Valve

M--Intermediate Stroke

B--Roller Tappet

F--Suction Chamber

J--Fuel Inlet

Position

C--Pressure Spindle

G--Pressure Valve

K--Hand Primer Pump

N--Suction and Discharge

D--Plunger

H--Pressure Chamber

L--Fuel Outlet

Stroke Position

injection pump. At the same time, plunger suction

As the pump camshaft (A) rotates toward the "high

pressure is permitting fuel to enter the suction

cam" intermediate stroke position (M), the roller tappet

chamber through the suction valve (I). With the suction

(B) and pressure spindle (C) cause the plunger (D) to

chamber charged with fuel, the pumping cycle begins

move against and compress the plunger spring (E).

again.

Plunger movement forces the fuel out of the suction

Fuel is allowed to flow in around the pressure spindle

chamber (F), through the pressure valve (G), and into

to lubricate the spindle as it moves back and forth in

the pressure chamber (H). The amount of fuel

housing. To prevent the fuel from entering the pump

discharged from the suction chamber is equal to the

crankcase, a rubber O-ring is positioned in the spindle

amount of fuel delivered for each stroke of the plunger.

bore of housing at the roller tappet end.

Towards the end of the intermediate stroke, the

spring-loaded pressure valve closes again.

Unscrewing the knurled knob on the hand primer pump

(K) and pulling upward causes the suction valve to

As the camshaft rotates toward the "low cam" or

open and fuel to flow into the suction chamber. When

suction and discharge position (N), plunger spring

the hand plunger is pushed downward, the suction

pressure causes the plunger, pressure spindle, and

valve closes, and fuel is forced out of the pressure

roller tappet to follow the camshaft.

valve.

Movement of the plunger pushes the fuel from the

pressure chamber, and delivers it to the fuel filters and

RG,115,JW7706 1924NOV972/2

13-566