TM 5-3805-281-24-1

Sub-System Diagnostics

1 WORK AND DRIVE LIGHT CIRCUIT DIAGNOSTIC PROCEDURES

IMPORTANT: Do not disconnect electrical connectors while the engine is running. Damage to Engine and

Pump Controller or other components may result. Disconnect connectors only when instructed during a

test or check.

NOTE: Before troubleshooting the circuits, clean all terminals in the monitor controller and harness connectors

using a non-conductive lubricating contact cleaner, then try the circuit operation again before proceeding. TY16324

Contact Cleaner can be used.

1/1

Remove fuse block cover.

WORK AND DRIVE

YES: Fuse is OK.

LIGHTS 20 AMP FUSE

9015

(F11) CHECK

Remove fuse from fuse block.

NO: Replace Fuse. If

15

fuse blows again, check

34

Using ohmmeter, check fuse for continuity.

for short.

Is continuity measured?

1/1

YES: Relay is OK.

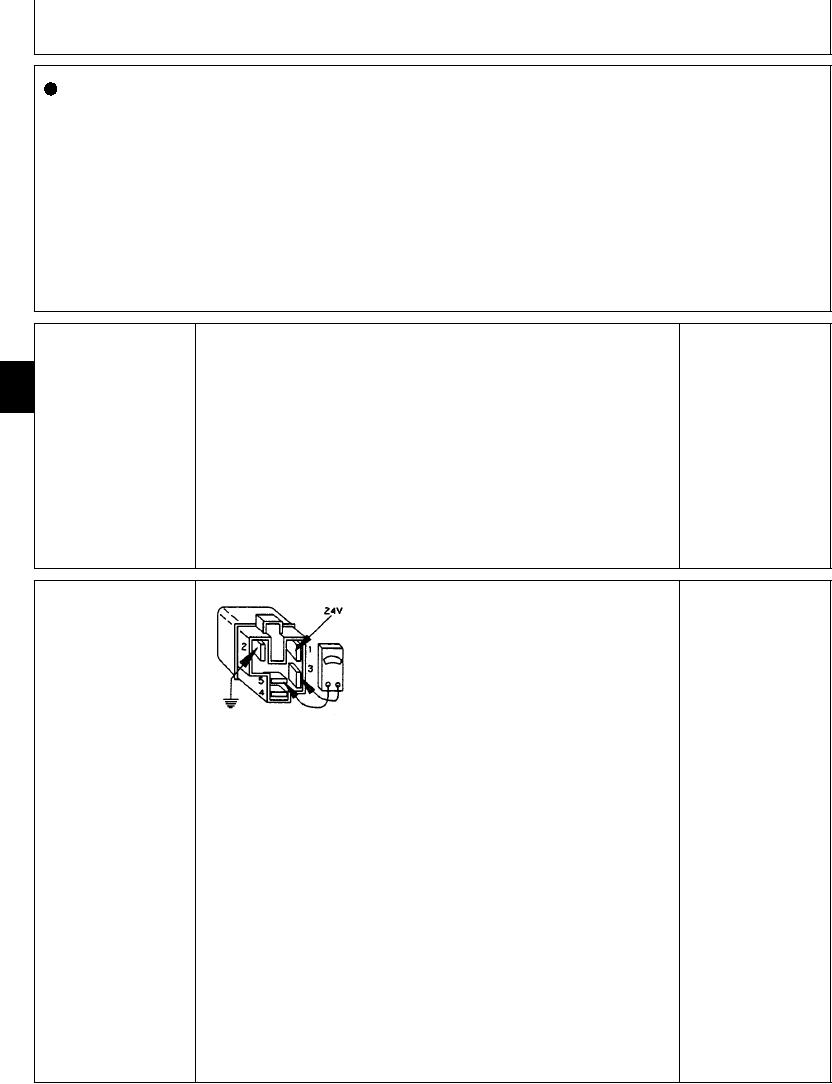

DRIVE LIGHT RELAY

1--24 Volt Terminal

(K4) CHECK

2--Ground Terminal

3--Relay Common

NO: Relay has failed.

4--Relay Normally Closed

Replace.

5--Relay Normally Open

Disconnect harness from relay.

Connect ohmmeter to terminals 3 and 5.

T7447BG

1914JAN91

Does ohmmeter read open?

Connect 24 volts to relay terminal 1 and ground terminal

2.

Does relay "click"?

With 24 volts still connected to terminal 1, connect

ohmmeter to terminals 3 and 5.

Does ohmmeter read continuity?

1/1