TM 5-3805-281-24-1

Diagnostic Information

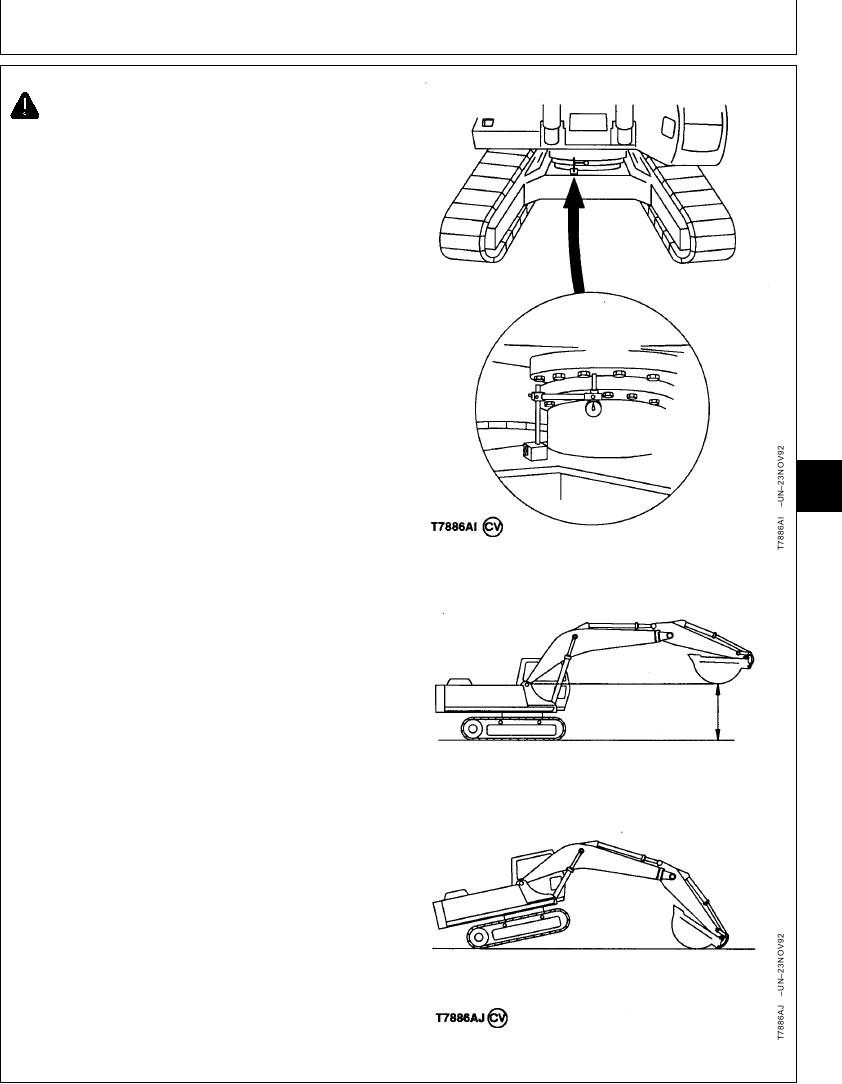

CAUTION: Stay clear of moving parts. Position

dial indicator so it can be seen while operator

can see you.

NOTE: Two people are needed to do the measurement.

One to operate the machine and one to take the

readings.

1. Check that swing bearing to main frame cap screws

are tight. (See Group 4350.)

Check that bearing is lubricated with the specified

grease. (See Track Adjuster, Working Tool Pivot,

Swing Bearing, and Swing Bearing Gear Grease in

General Information Section.)

Check that bearing rotation is smooth and without

noise.

2. Install the dial indicator with needle point contacting

bottom face of swing bearing outer race.

9020

15

3. Move boom and arm to position shown with bucket off

19

the ground.

4. Turn dial indicator to zero.

5. Lower boom to raise front idlers off the ground

approximately 500 mm (20 in.)

6. Record dial indicator reading.

If reading is more than maximum allowable, check for

steel ball and spacer wear. Repair or replace swing

bearing as needed. (See Group 4350.)

Swing Bearing--Specification

Play .......................................................... 1.4 mm (0.055 in.) or less new

Play............................................................... 4.7 mm (0.185 in.) maximum

used

CED,TX08227,3160

1930MAY982/2

5-22