TM 5-3805-281-24-1

Adjustments

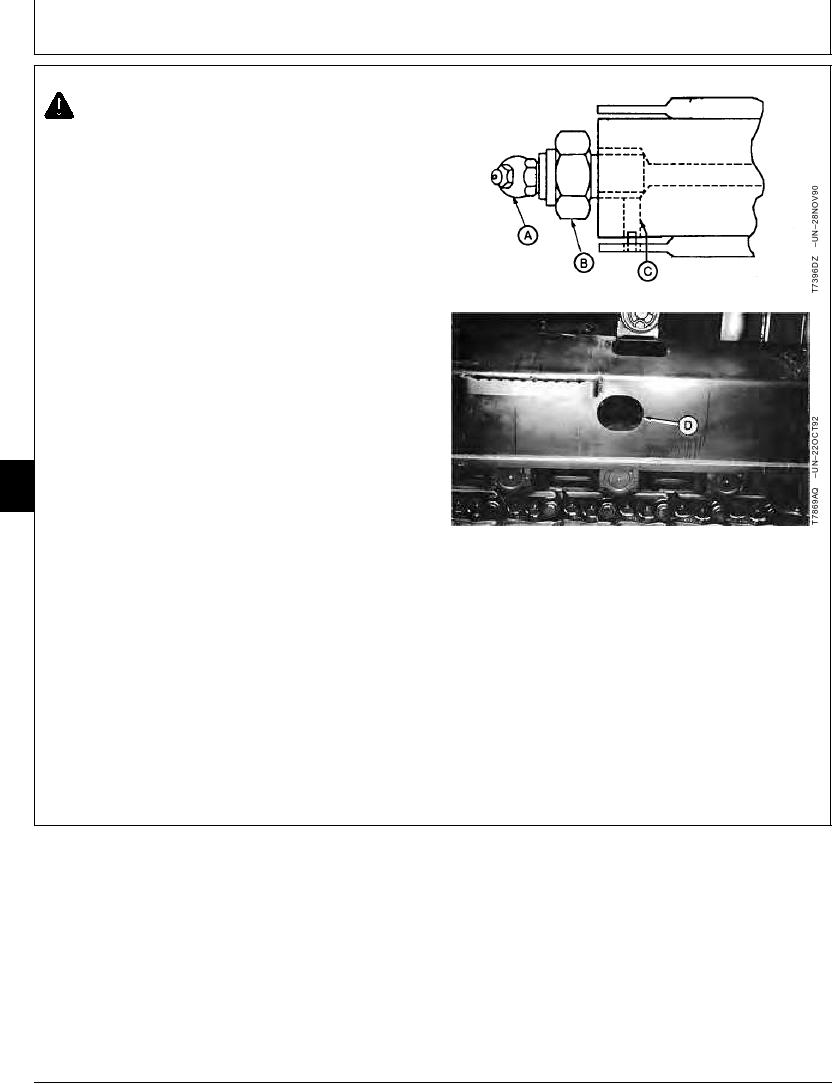

CAUTION: High pressure grease in track

adjuster cylinder. Do not remove grease fitting

or nut and valve assembly to release grease.

IMPORTANT: Prevent possible damage to track

components. Do not use the grease

fitting on track adjuster cylinder for

lubrication. Use this grease fitting only

for track sag adjustment.

5. To decrease track sag, add multi-purpose grease to

track adjuster cylinder through grease fitting (A) located

in access hole (D) in track frame. Use a grease gun

with a maximum capacity of 68 950 kPa (690 bar) (10

000 psi).

To increase track sag, loosen nut and valve assembly

(B) one turn to release grease from track adjuster

cylinder through bleed hole (C) in rod.

Tighten nut and valve assembly when track sag is

9020

correct.

20

2

Nut and Valve Assembly-to-Track Adjuster Cylinder--Specification

Torque ......................................................................... 147 Nm (108 lb-ft)

A--Grease Fitting

B--Nut and Valve Assembly

NOTE: If piston in track adjuster cylinder does not move,

C--Bleed Hole

remove the cylinder to make repairs. (See

D--Access Hole

Remove and Install Track Adjuster in Group

0130.)

CED,TX08227,3161

1930MAY983/3

5-24