TM 5-3805-281-24-1

Theory of Operation

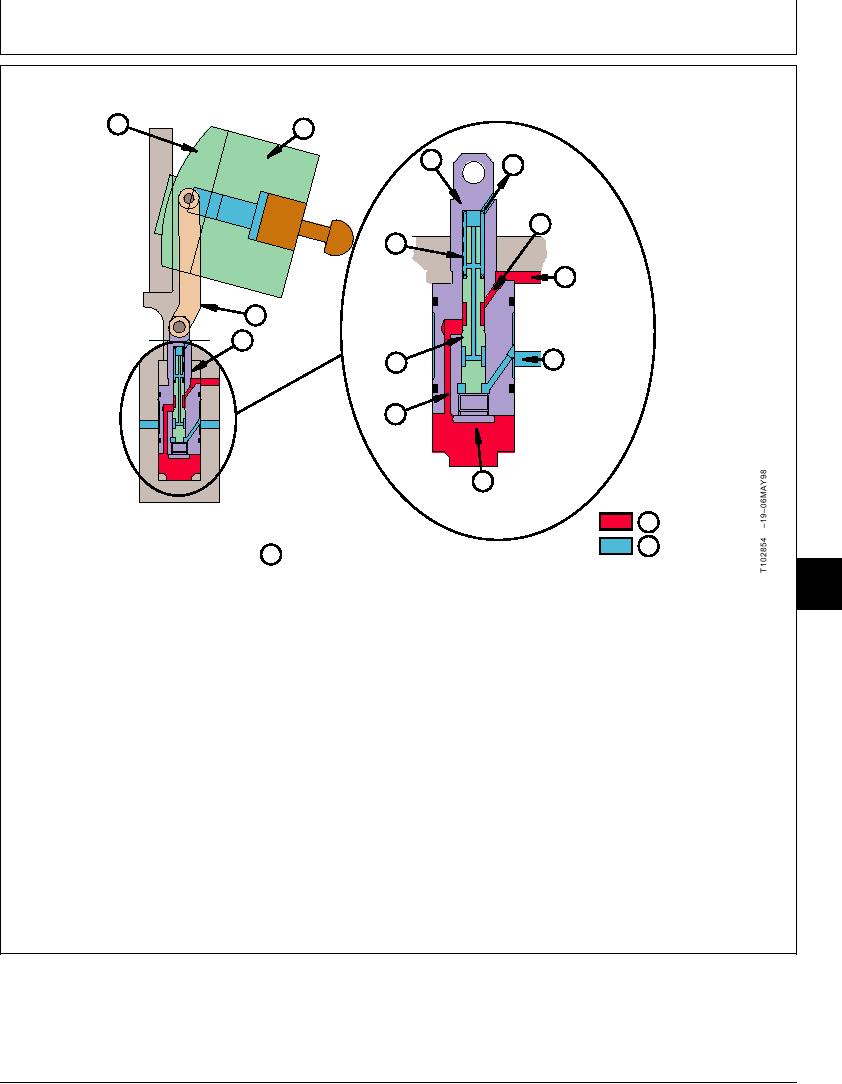

PROPEL MOTOR SLOW SPEED OPERATION

VALVE A

B ROTARY

PLATE

GROUP

D

H

TO MOTOR

SERVO

CASE DRAIN

PISTON

I

CHAMBER

G

"A"

SPRING

J

FROM

MOTOR

C LINK

PORT

D SERVO

PISTON

K

F

FROM PROPEL

SPOOL

SPEED CHANGE

SOLENOID

E

VALVE

ORIFICE

L

CHAMBER "B"

M SUPPLY OIL

N RETURN OIL

T102854

O SLOW SPEED

9025

05

87

group. For circuit operation, see Propel Motor Speed

The servo piston (D) is connected by a link (C) to the

Change Circuit Operation in this group.)

valve plate (A). When servo piston is extended or

retracted by supply oil pressure the angle of the rotary

Supply oil from motor port (J) is now applied to both

group (B) changes and the propel speed changes

chamber "A" (I) and chamber "B" (L) at the same time.

accordingly.

Supply oil pressure in chamber "B" acts on a larger

area than the supply oil pressure in chamber "A"

When propel speed switch is set to slow speed (turtle)

causing the servo piston to move upward increasing

the control signal from the propel speed change

rotary group swash angle. As the swash angle

solenoid valve to the bottom of speed selector valve

increases, the stroke of each piston is increased

spool (F) is too low to shift the spool against the spring

resulting in slower revolution of the propel motor for

(G). The spool (F) is pushed down by the spring (G).

slower propel speed.

(For operation of propel speed change solenoid valve,

see Proportional Solenoid Valve Operation in this

CED,TX08227,3099

1922APR981/1