TM 5-3805-281-24-1

Tests

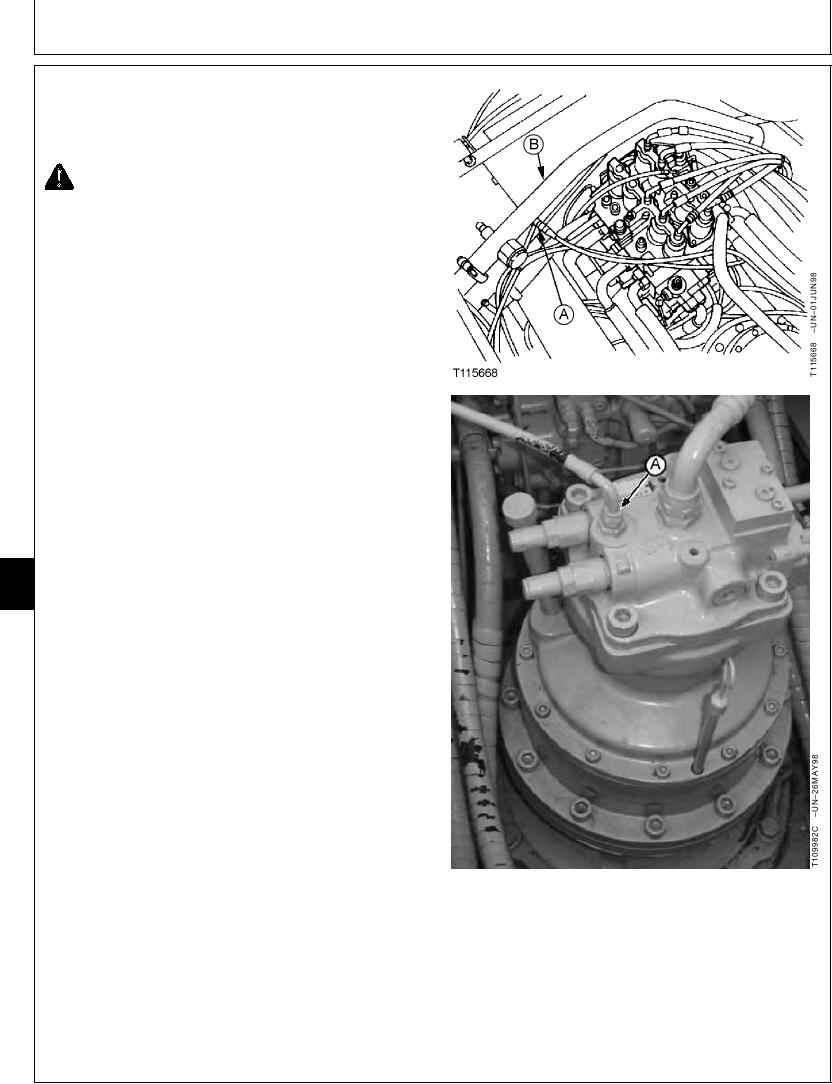

5. Disconnect swing motor drain line (A) at the return

manifold (B). Install a cap on elbow. Put drain line in a

calibrated container.

CAUTION: To avoid personnel injury, clear area

of all bystanders before doing test. Slowly

swing through one complete revolution to

ensure that the area is clear of objects before

doing test.

6. Raise and lower boom to pressurize hydraulic tank.

7. Operate the machine at specifications.

Engine--Specification

Engine........................................................................................... Fast Idle

Work Mode Selector--Specification

Position ........................................................................................ Dig Mode

E Mode Switch--Specification

Position .................................................................................................. Off

HP Mode Switch--Specification

9025

Position .................................................................................................. Off

25

138

Auto-Idle Switch--Specification

Position .................................................................................................. Off

8. Operate swing function for one minute. Record the

amount of leakage. Repeat for swing in opposite

direction.

9. Operate swing function at stall for one minute. Put the

bucket against an immovable object or in a trench then

hold swing control lever fully actuated to stall swing

function. Record the amount of leakage.

Repeat procedure by stalling the motor in several

position. Repeat procedure in the opposite direction.

10. Compare amount of leakage to specifications.

A--Swing Motor Drain Line

Continued on next page

CED,TX08227,3148

1930MAY983/4

6-285