TM 5-3805-281-24-2

Hydraulic System

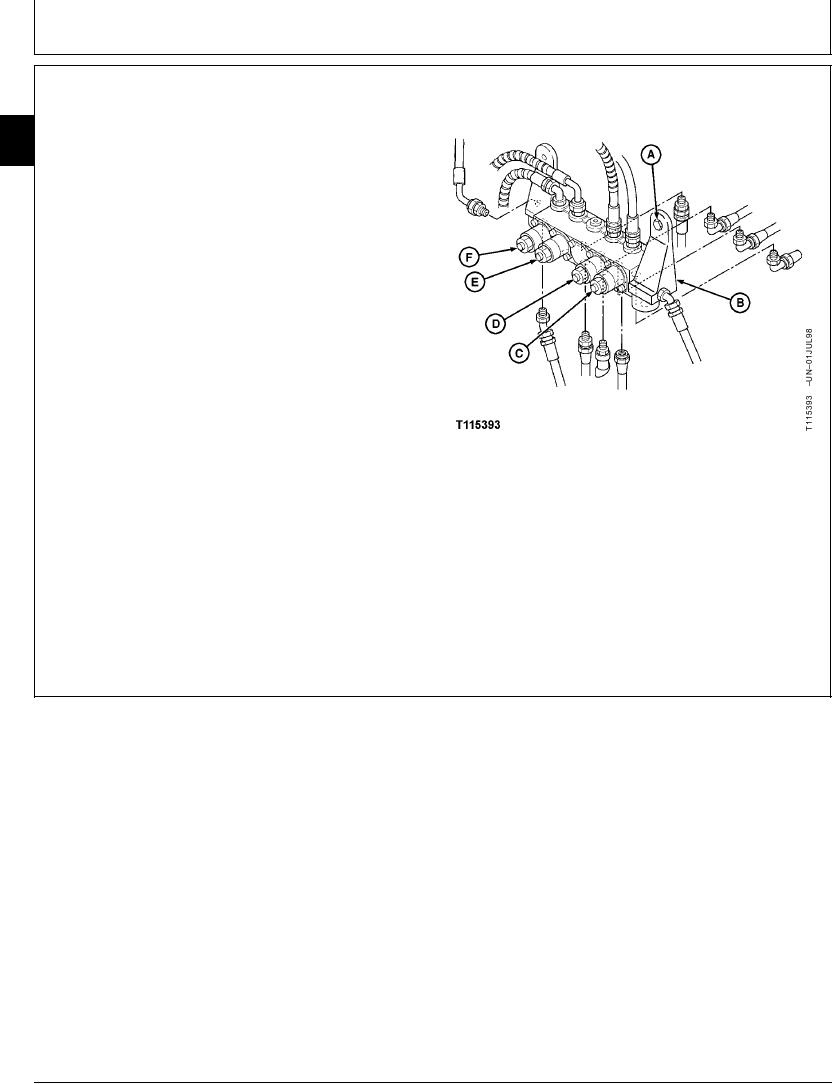

3. Disconnect wiring harness connectors at each solenoid

valve (C--F).

33

3360

4. Remove cap screws (A) to remove solenoid valve

66

manifold block (B). Repair or replace part as

necessary.

5. Install solenoid valve manifold (B) using two cap

screws (A). Tighten cap screws.

Solenoid Valve Manifold-to-Control Valve Mounting Bracket Cap

Screw--Specification

Torque ............................................................................. 20 Nm (16 lb-ft)

6. Connect wiring harness connectors.

7. Connect lines.

8. Check pressure setting of proportional solenoid valves.

(See Proportional Solenoid Valve Test and Adjustment

in Group 9025-25.)

A--Cap Screw (2 used)

B--Solenoid Valve Manifold

C--Arm Regenerative Solenoid Valve (BLU/WHT

and BLU/ORN Wiring Leads)

D--Speed Sensing Solenoid Valve (RED/WHT and

RED/YEL Wiring Leads)

E--Propel Speed Change Solenoid Valve

(LGRN/RED and LGRN/BLK Wiring Leads)

F--Power Boost Solenoid Valve (BLK/RED and

BLK/BLU Wiring Leads)

CED,OUOE026,55

1926JUN984/4

19-102