TM 5-3805-281-24-2

Hydraulic System

12. Check cap seal. Seal must fit tight against O-ring and

not turn. If seal can be turned, it has been stretched

33

too much and can be damaged during assembly into

3360

cylinder barrel.

181

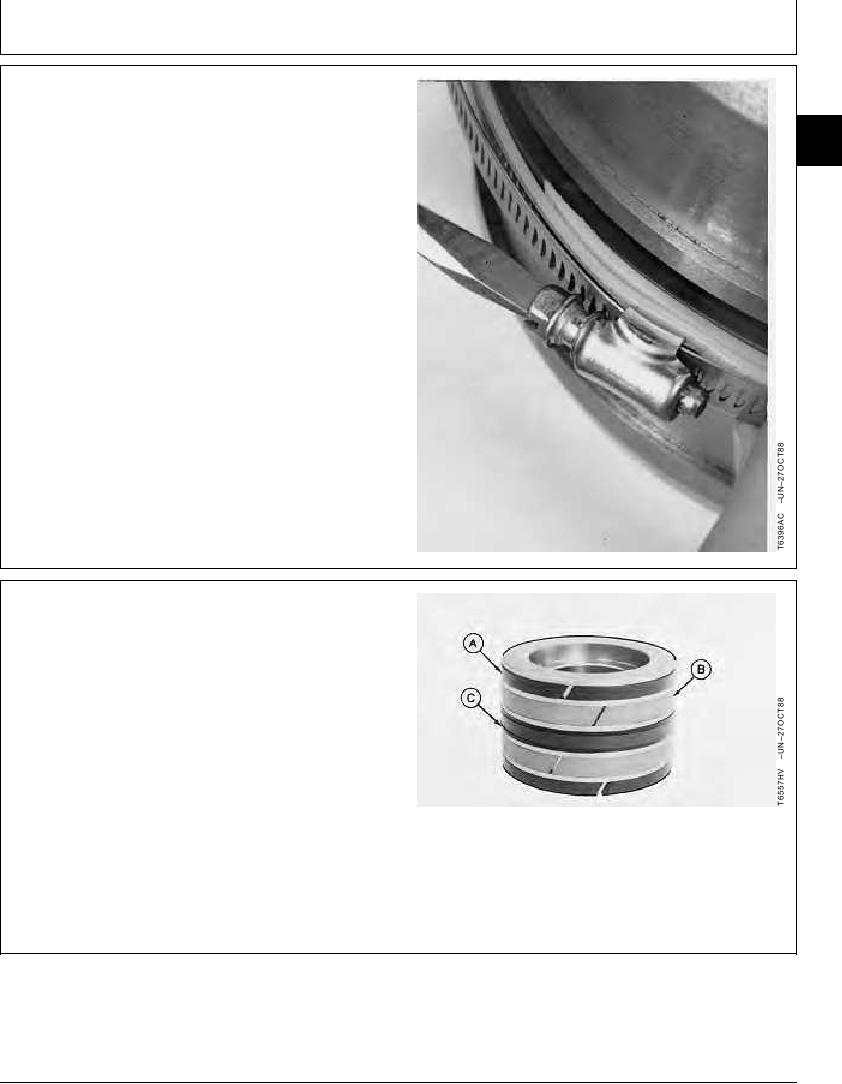

13. For a cap seal that has been stretched too much,

shrink it to its original size using a ring compressor or

a plastic tie band and hose clamp.

When using a ring compressor, put a piece of shim

stock between cap seal and compressor at joint so it

does not damage seal.

When using a plastic tie band and hose clamp, grind

a taper on one end of tie band. Install tie band with

taper against cap seal. Before tightening the hose

clamp, check to be sure tie band is under hose clamp

all around piston.

CED,OUOE026,12 1919JUN985/10

14. Install a backup ring (C) on each side of cap seal.

15. Install wear rings (B) and rings (A).

Turn the rings so slits are 180 from each other.

A--Ring (2 used)

B--Wear Ring (2 used)

C--Backup Ring (2 used)

Continued on next page

CED,OUOE026,12 1919JUN986/10

19-208