TM 5-3805-294-23-1

0057

Control Unit Response - Continued

The ECU will use the high-pressure fuel pump position sensor input to determine piston position.

If a high-pressure fuel pump position sensor DTC accompanies DTC 637.02, the engine cannot be started and will

stall if running until at least one of the two codes is repaired.

Maximum engine power is derated up to 50 percent.

TROUBLESHOOTING PROCEDURE

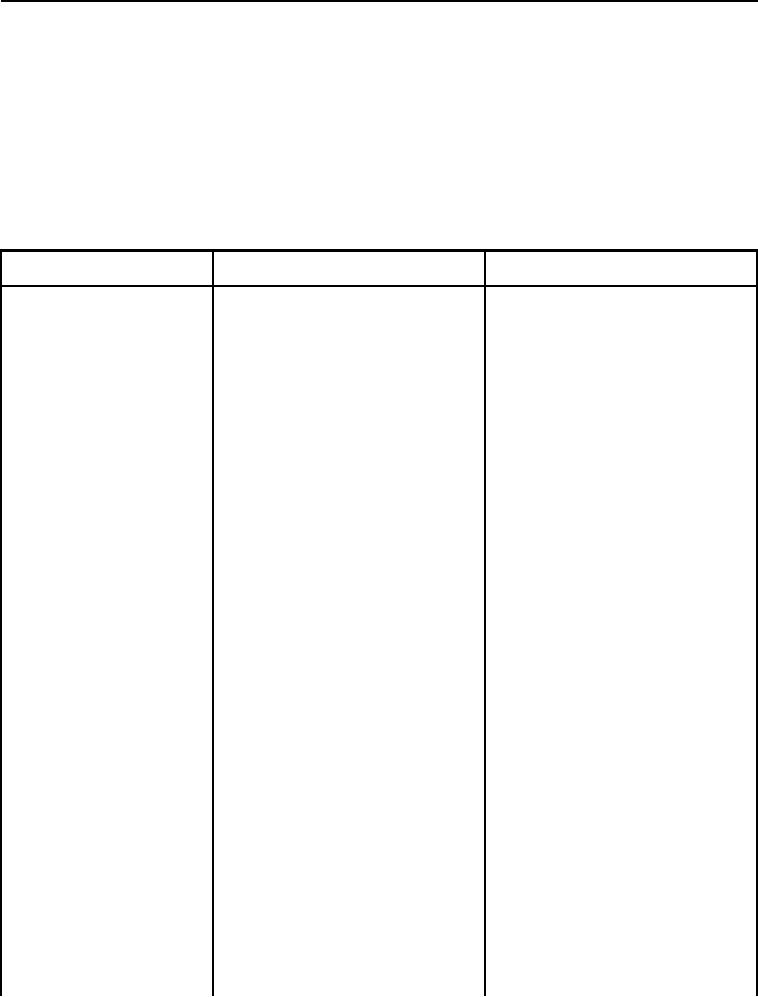

Table 1. DTC 637.02 - Crankshaft Position Signal Invalid.

Test or Inspection

Corrective Action

Malfunction

1.

Verify key switch is in OFF

1.

Engine Wiring

position (TM 5-3805-294-10).

Harness Connector

X01 Has Damage or

(Volume 5, WP 0794)

Loose Sockets.

2.

Disconnect engine wiring

harness connector X01 from

crankshaft position sensor.

(Volume 5, WP 0800, Figure

82)

3.

Visually inspect engine wiring

1.

If damaged or has loose

harness connector X01 for

sockets, repair connector X01

damage and loose sockets.

(Volume 4, WP 0511) or

replace engine wiring

harness. (Volume 4,

WP 0510) Restore machine to

original condition and perform

Harness Diagnostic Mode

Test. (Volume 3, WP 0345)

2.

If not damaged and does not

have loose sockets, proceed to

Malfunction 2.

1.

Remove crankshaft position

2.

Crankshaft Position

Sensor Has

sensor. (Volume 3, WP 0405)

Damage or Loose

Pins.

2.

Visually inspect crankshaft

1.

If damaged or has loose pins,

position sensor for damage

replace crankshaft position

and loose pins. (Volume 5,

sensor. (Volume 3, WP 0405)

WP 0800, Figure 82)

Restore machine to original

condition and perform Harness

Diagnostic Mode Test.

(Volume 3, WP 0345)

If not damaged and does not

2.

have loose pins, proceed to

Malfunction 3.

0057-2