TM 5-3805-294-23-1

0058

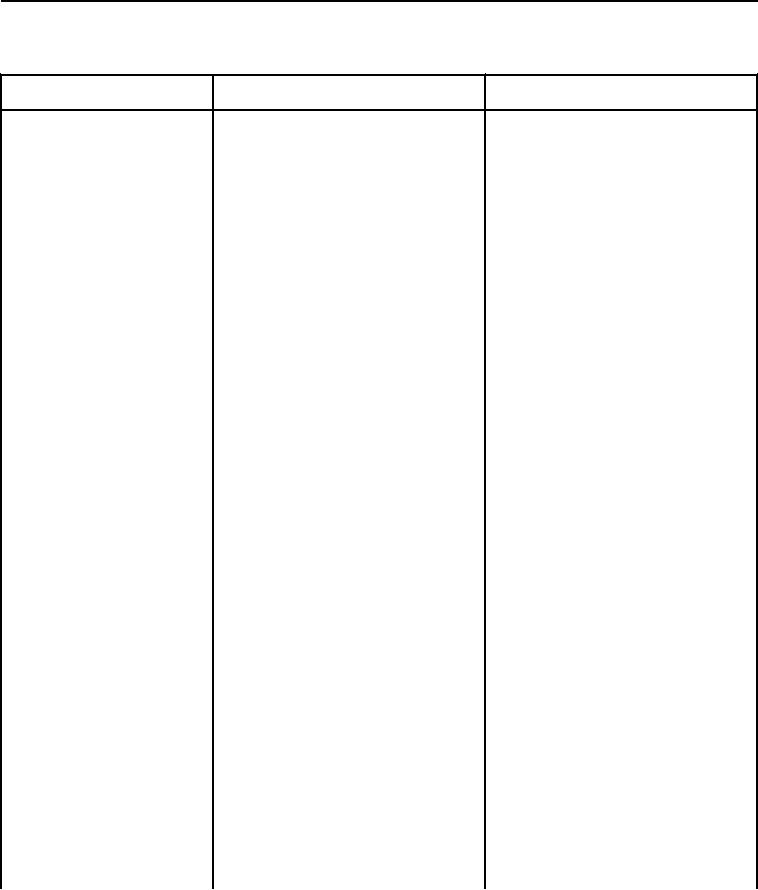

Table 1. DTC 637.05 - Crankshaft Position Sensor Circuit Has High Resistance - Continued.

Test or Inspection

Corrective Action

Malfunction

2.

Measure voltage (Volume 3,

WP 0369) between engine

wiring harness connector J03

socket F4 (Volume 5,

WP 0800, Figure 48) and

known good ground. Note

reading.

3.

Turn key switch to OFF

1.

If less than 0.5 volts, proceed

position (TM 5-3805-294-10).

to Malfunction 11.

(Volume 5, WP 0794)

2.

If greater than 0.5 volts,

replace engine wiring

harness. (Volume 4,

WP 0510) Restore machine to

original condition and perform

Harness Diagnostic Mode

Test. (Volume 3, WP 0345)

1.

Install crankshaft position

11.

Intermittent Open

Circuit.

sensor. (Volume 3, WP 0405)

2.

Reconnect all electrical

connectors.

3.

Turn key switch to ON position,

but DO NOT START ENGINE

(TM 5-3805-294-10). (Volume

5, WP 0794)

4.

Perform Harness Diagnostic

Mode Test. (Volume 3,

WP 0345) Note if DTC 637.05

is an active DTC.

5.

Turn key switch to OFF

1.

If DTC 637.05 is still an active

position (TM 5-3805-294-10).

DTC, proceed to Malfunction

12.

(Volume 5, WP 0794)

2.

If DTC 637.05 is not an active

DTC, problem was not found

and may have been missed

during troubleshooting

procedure. Restart procedure

at Malfunction 1.

0058-5