TM 5-3805-294-23-1

0062

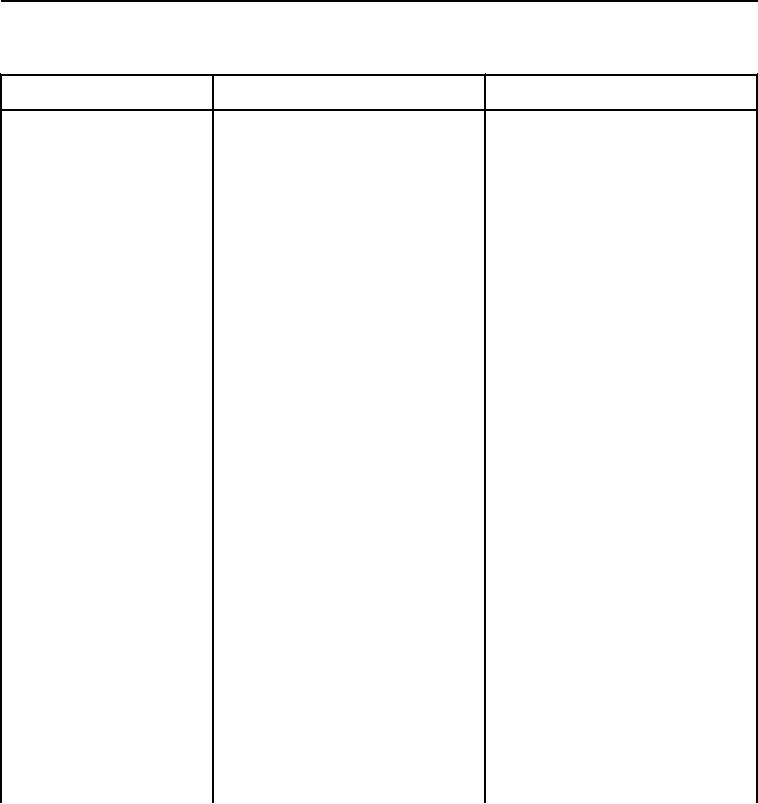

Table 1. DTC 637.10 - Crankshaft Position Signal Rate of Change Abnormal

Test or Inspection

Corrective Action

Malfunction

Visually inspect engine wiring

1.

If damaged or no twists,

20.

Engine Wiring

harness between connectors

replace engine wiring

Harness Between

harness. (Volume 4,

Connectors J03 and

J03 (Volume 5, WP 0800,

X01 Are Damaged

Figure 48) and X01 (Volume

WP 0510) Restore machine to

or Wires Are Not

original condition and perform

5, WP 0800, Figure 82) for

Twisted

Harness Diagnostic Mode

damage and wires not twisted

Throughout Wiring

Test. (Volume 3, WP 0345)

throughout wiring harness.

Harness.

2.

If not damaged and wires are

twisted correctly, proceed to

Malfunction 21.

Verify if crankshaft position

1.

If sensor was replaced,

21.

Replace Crankshaft

sensor was replaced during

proceed to Malfunction 22.

Position Sensor.

this troubleshooting

2.

If sensor was not replaced,

procedure.

replace crankshaft position

sensor. (Volume 3, WP 0405)

Restore machine to original

condition and perform

Harness Diagnostic Mode

Test. (Volume 3, WP 0345)

1.

Install crankshaft position

22.

ECU Faulty.

sensor. (Volume 3, WP 0405)

2.

Replace ECU. (Volume 4,

WP 0508)

3.

Reconnect all electrical

connectors.

4.

Turn key switch to ON position;

START ENGINE (TM

5-3805-294-10). (Volume 5,

WP 0794)

5.

Clear and refresh DTCs.

(Volume 3, WP 0362) Note if

DTC 637.10 is an active DTC.

0062-9