TM 5-3805-294-23-1

0124

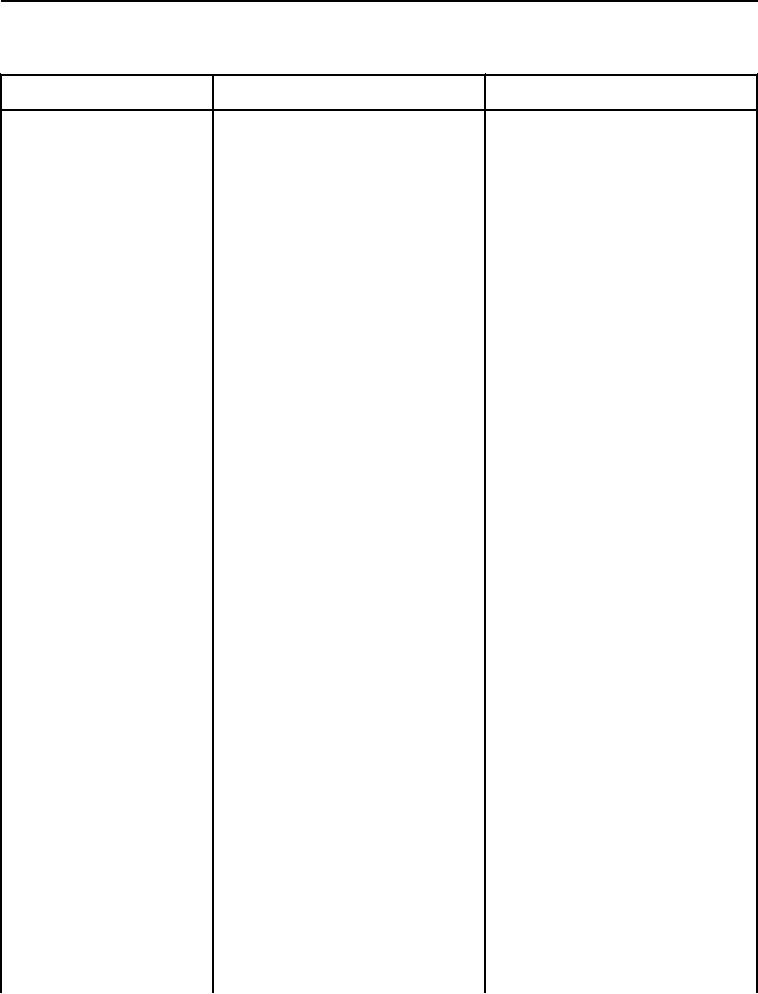

Table 1. Engine Control Unit (ECU) Does Not Communicate With Service Advisor - Continued.

Test or Inspection

Corrective Action

Malfunction

Visually inspect DIAG 5A F18

1.

If damaged or has loose

13.

DIAG 5A F18 Fuse

fuse sockets for damage or

sockets, replace cab wiring

Sockets Are

loose sockets. (Volume 5,

harness. (Volume 4,

Damaged or Are

Loose.

WP 0800, Figure 163)

WP 0504) Restore machine to

original condition.

2.

If not damaged and does not

have loose sockets, proceed to

Malfunction 14.

1.

Turn key switch to ON position,

14.

22 - 28 Volts Not

but DO NOT START ENGINE

Present Between

(TM 5-3805-294-10). (Volume

DIAG 5A F18 Fuse

Socket 1 and

5, WP 0794)

Ground.

2.

Measure voltage (Volume 3,

WP 0369) between DIAG 5A

F18 fuse socket 1 (Volume 5,

WP 0800, Figure 163) and a

known good ground. Note

reading.

3.

Turn key switch to OFF

1.

If between 22 -28 volts,

position (TM 5-3805-294-10).

proceed to Malfunction 15.

(Volume 5, WP 0794)

2.

If not between 22 - 28 volts,

restore machine to original

condition. Discontinue this

troubleshooting procedure and

perform All 24 VDC Circuits Do

Not Operate. (Volume 2,

WP 0169)

Visually inspect connector X1

1.

If damaged or has loose

15.

Connector X1

for damage or loose sockets.

sockets, replace machine

Damaged or Has

wiring harness. (Volume 4,

Loose Sockets.

(Volume 5, WP 0800, Figure

144)

WP 0516) Restore machine to

original condition.

If not damaged or does not

2.

have loose sockets, proceed to

Malfunction 16.

Measure resistance (Volume

1.

If continuity is present,

16.

Open Circuit

proceed to Malfunction 17.

Between Connector

3, WP 0369) between

X1 Socket A and

connector X1 socket A

2.

If continuity is not present,

Ground.

(Volume 5, WP 0800, Figure

replace machine wiring

144) and a known good

harness. (Volume 4,

ground. Note reading.

WP 0516) Restore machine to

original condition.

0124-5