TM 5-2420-230-24-1

Hoses and Fittings.

b.

NOTE

Most fluid piping system sizes are measured by dash numbers. These are universally used

abbreviations for the size of the component expressed as the numerator of the fraction with the

denominator always being 16. For example, a -04 port is 4/16 or inch. Dash numbers are usually

nominal (in name only) and are abbreviations that make ordering of components easier.

(1)

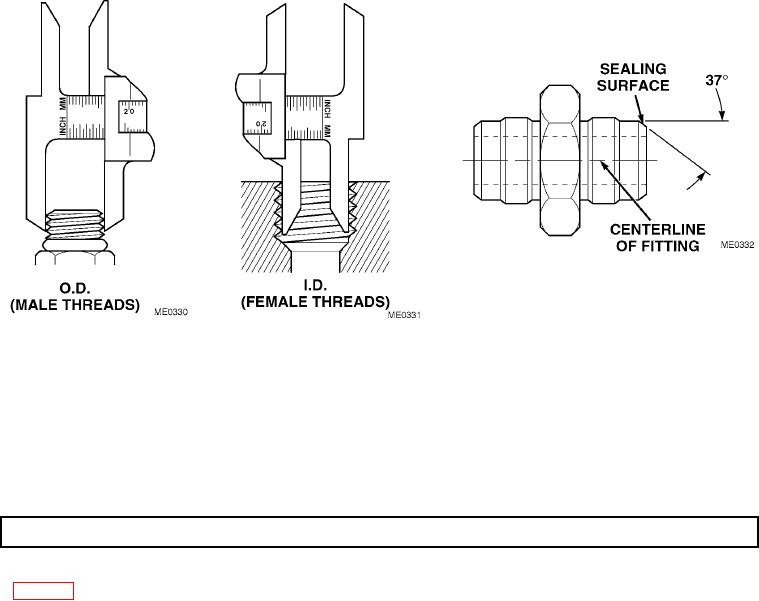

Measure the I.D./O.D. diameter with a caliper as shown.

(2)

Under the headings MALE THREAD O.D. and FEMALE THREAD I.D., match the measurements with the row

in table to determine proper torque.

(3)

To find the sealing surface angle, use a protractor and measure the sealing surface parallel to the centerline of the

fitting.

E-4. ADI-RECOMMENDED TORQUE TABLES.

The torque values in this paragraph must be used whenever applicable. If the type or size fastener being used is not listed, refer

to Para E-5. . When using the ADI torque specification, note the following:

a. "The Recommended Assembly Torques" are for plain-finish, uncoated fasteners.

b. The torque specifications in this paragraph only apply to bolt and nut applications.

c. When a flexible gasket is used, multiply the value shown by 0.8 to find the correct torque.

d. Capscrews must have the following thread engagement: 1.5 thread diameters in steel, 2.5 thread diameters in

aluminium.

E-3