TM 5-2420-230-24-1

Maintenance & Service Manual

R & HR32000 3 & 6 Speed LD

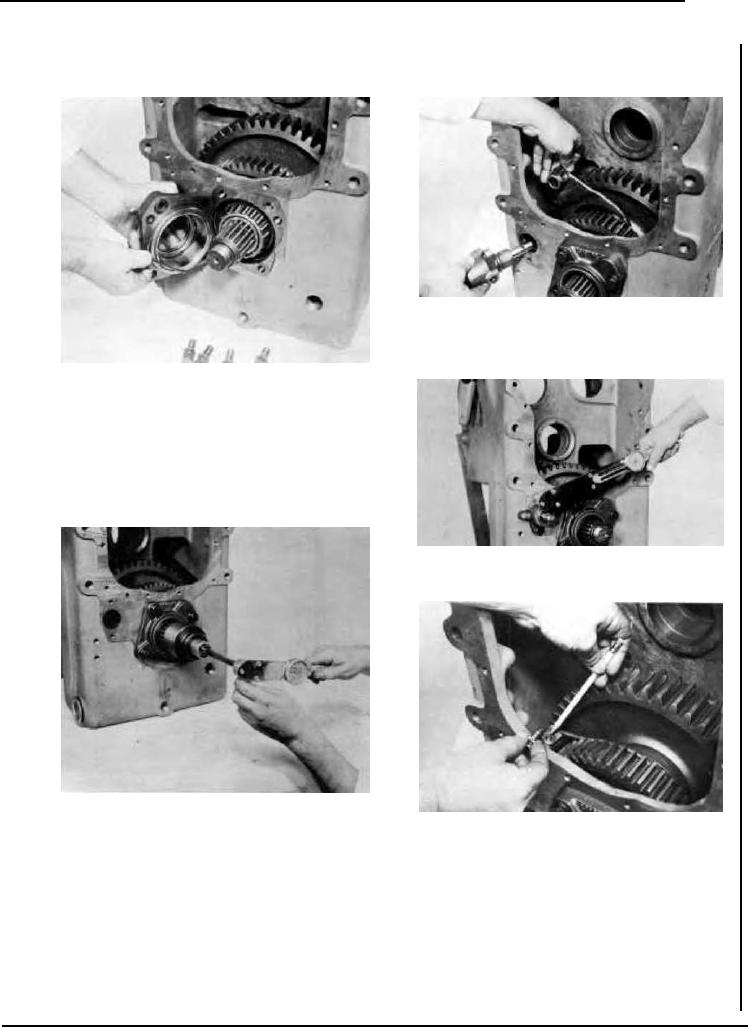

Figure 11

Locate high-low range shift fork in shift hub with offset of fork

toward gear. Insert rail support and rail into bore in transmission

housing and into shift fork.

Figure 9

Using new "O" rings install rear output bearing cap and taper

bearing cup on transmission case. Lube opening in bearing cap

must be aligned with lube opening in case. Tighten bearing cap

bolts to specified torque. (See torque chart.)

Install front bearing cap and shims. Tighten bolts to specified

Loosen front bearing cap bolts.

Figure 12

Tighten support bolts to specified torque. (See torque chart).

Figure 10

Using a inch lb. torque wrench, determine the rolling torque of

Figure 13

the output shaft and record. Tighten front bearing cap bolts to

Locate lockscrew hole in shift rail with hole in shift fork. Install

specified torque. Check rolling torque with bolts tight. Torque

lockscrew, tighten securely and lockwire to prevent loosening.

must be 8 to 8 inch lbs. [0.68 - 0.90 N.m] more than when bear-

ing cap bolts were loose. Add or omit shims on the front bearing

Proceed with Figure 228 in the R & HR 32000 3-Speed Section.

cap to achieve the proper preload.

--87--

F-132