9008-36

TM 5-2420-230-24-1

3. Use a grinder to remove any welds or extra metal

still on the bucket so that the new bottom cutting

edge will fit the bucket.

4. Put the new bottom cutting edge in position and

make several tack welds to hold it.

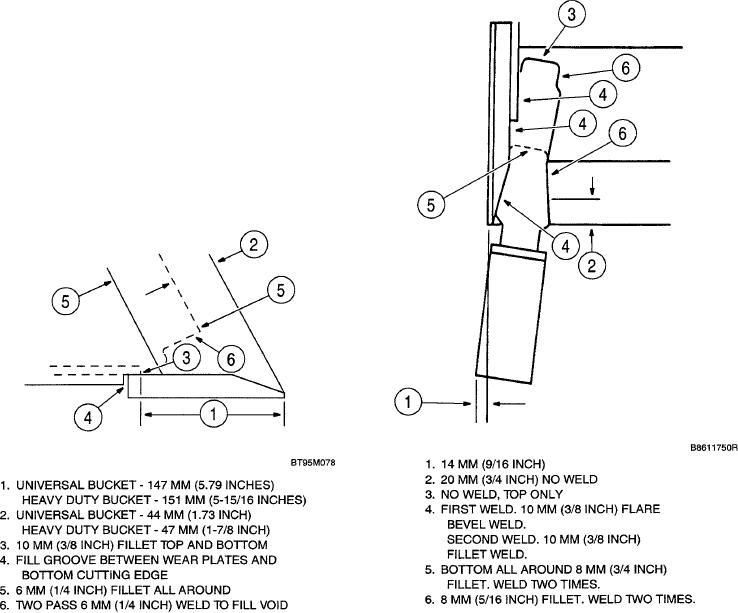

5. See the following illustration for the weld

locations and specifications. DO NOT make any

welds on the inside of the bucket except the

bottom of the bucket to the bottom cutting edge.

Use E7018 welding rod to weld the bottom

cutting edge in position.

7. Weld the remaining bucket teeth to the bottom

6. See the following illustration. Install the corner

cuffing edge according to the instructions in this

bucket teeth and weld the bucket teeth in

section.

position. Use E7018 welding rod.

Replacing Side Cutting Edge

1. Use carbon arc rod or an acetylene cutting torch

to remove the welds that hold the side cutting

edge.

2. Use a grinder to remove any welds or extra metal

still on the bucket so that the new side cutting

edge will fit the bucket.

3. Use E7018 welding rod to weld the side cutting

edge to the bucket with a 6 mm (1/4 inch) fillet all

around the side cutting edge.

H-72

Bur 6-42130

Issued 3-01

Printed in U.S.A.